Introduction

How to get metal through a metal detector is a pressing issue for food producers. This question can easily be related to a true industrial problem that exists in the field of food processing: how do you detect unwanted metal contamination in products wrapped up by aluminum foil packaging without raising false alarms?

Let’s explore this issue, why it’s important and how state-of-the-art food metal detectors are engineered to deliver safe product without sacrificing productivity.

The Challenge with Foil Packaged Items

Aluminum foil is, of course, made of metal. So when you run a foil-wrapped food product through conventional metal detectors, the detector identifies the foil as a metal contaminant. That’s why many manufacturers struggle to detect real foreign objects inside such packaging.

Imagine this:

You produce chocolate bars wrapped in shiny foil. Your metal detector good system flags every single bar as “contaminated” — even when there’s no actual metal inside. Frustrating, right?

That’s why metal detectors for aluminum foil packaged products were developed — specialized machines that can differentiate between the known metal (the foil) and unknown foreign metals hidden within the food.

Why Foil Packaging Makes Metal Detection Difficult

Foil acts as a conductive layer that interferes with the electromagnetic field of a detector. Traditional metal detectors rely on detecting disturbances in this field — so the foil packaging essentially “blinds” them.

To solve this, metal detectors for sale today come with multi-frequency technology. This allows the detector to switch between frequencies, filtering out the “noise” caused by the foil while still picking up unwanted metallic contaminants.

High-end models, such as those with a metal detector with color display, even visualize detection patterns in real time — allowing operators to see what the detector “sees.”

How to Get Metal Through a Metal Detector — The Safe, Legitimate Way

When we talk about how to get metal through a metal detector, we’re referring to a safe, industry-approved method — not evasion, but precision detection.

Modern metal detectors designed for foil packaging use advanced technology, such as ferrous-in-foil detection. Instead of using a balanced coil system (like standard detectors), these units rely on magnetic field detection.

Here’s how it works:

The metal detector detect ferrous (iron-based) materials even inside foil packaging.

It ignores the consistent metallic signal from the foil itself.

It can find contaminants like stainless steel fragments, iron shavings, or tiny metal pieces without triggering false positives.

This calibration process is key to how to get metal past a metal detector safely. It’s all about teaching the system what’s “normal” (the foil) and what’s “abnormal” (foreign metals).

Can Metal Detectors Detect Non-Metallic Items?

You might wonder: Can a metal detector detect plastic?

The answer is — not directly. Metal detectors identify conductive materials (metals). So they won’t detect plastic, glass, or bone unless those materials contain metallic traces.

This is why many factories pair metal detectors with X-ray inspection systems — to cover non-metallic contaminants, too.

What Can Metal Detectors Detect

Depending on their configuration and sensitivity, metal detectors can detect:

- Ferrous metals (like iron, steel)

- Non-ferrous metals (like copper, brass, aluminum)

- Stainless steel contaminants

However, they cannot detect:

- Pure plastics

- Glass

- Rubber

For multi-layer packaging or aluminum foil products, specialized detector of metal systems are essential.

Do Metal Detectors Detect Alcohol?

One common question people ask is: do metal detectors detect alcohol?

In short — no. Metal detectors detect metals, not liquids or alcohol content. However, alcohol containers with metallic caps, seals, or foils can trigger a response.

How to Block a Metal Detector

Some people online talk about how to block a metal detector or how to get metal past a metal detector in the context of evasion — such as concealing objects.

In the food manufacturing industry, though, “blocking” refers to the intentional shielding used in machine calibration — for instance, adjusting sensors to “ignore” known foil interference.

Trying to bypass a metal detector outside this controlled, professional use is unsafe and unethical.

The Science Behind How Metal Detectors Work in Foil Applications

To truly understand how do metal detectors work in foil applications, imagine this process:

The detector emits a magnetic field.

The aluminum foil packaging reflects that field consistently.

The detector’s software learns this pattern and classifies it as “background.”

Any deviation — say a stainless steel fragment — disrupts this pattern and triggers an alarm.

Modern systems like those from Easyweigh use digital signal processing (DSP), multi-frequency scanning, and automatic calibration to ensure precision detection even in complex environments.

Types of Metal Detectors for Foil Packaged Foods

Here are some of the most common configurations used in the industry:

Ferrous-in-Foil Detectors: Ideal for detecting metal contaminants in aluminum foil–wrapped products.

Pipeline Metal Detectors: Perfect for sauces, jams, and liquid foods.

Conveyor Belt Metal Detectors: Used for packaged or boxed items.

Free-fall Detectors: Designed for powders or grains.

Many of these come with waterproof metal detector options for washdown environments, ensuring hygienic operation.

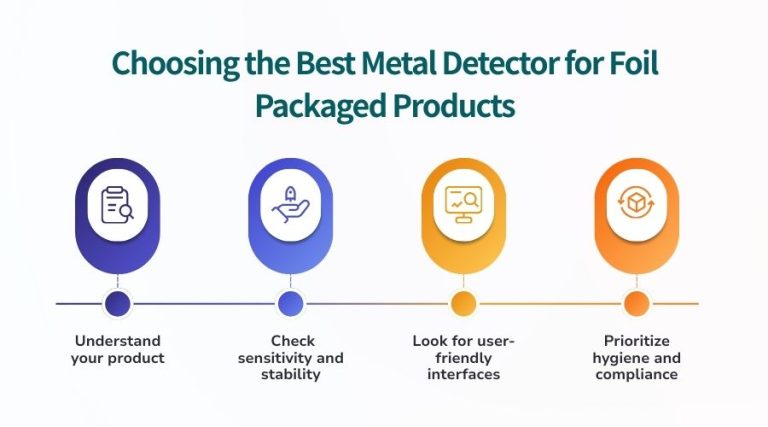

If you’re in the market for metal detectors for sale, here are a few tips:

Understand your product — foil-wrapped chocolates, aluminum trays, or vacuum-sealed meats each require different detection frequencies.

Check sensitivity and stability — the best metal detector balances both.

Look for user-friendly interfaces — such as a metal detector with color display.

Prioritize hygiene and compliance — choose waterproof, stainless-steel designs certified for food use.

How to Integrate a Metal Detector into Automated Production Systems

Integrating a metal detector into your production line involves:

Identifying critical control points in your food safety plan.

Ensuring detectors are placed after major processing stages (like filling, sealing, or packaging).

Linking detectors to automatic reject systems.

Regular calibration to ensure ongoing accuracy.

Proper integration minimizes downtime and maximizes safety for food.

Why Specialized Metal Detectors Matter for Foil Packaging

Regular detectors struggle with foil. Specialized systems don’t.

That’s why metal detectors for aluminum foil packaged products are crucial — they allow businesses to keep using foil for freshness, while maintaining the highest food safety standards.

These detectors ensure that getting metal through a metal detector is a controlled, legitimate, and safe process — not a loophole.

Conclusion

To wrap it up — learning how to get metal through a metal detector is about understanding, not bypassing. It’s about optimizing your detection process to ensure both accuracy and compliance.

Foil packaging adds complexity, but with the right technology — such as Easyweigh’s advanced metal detectors — manufacturers can ensure 100% product integrity, zero contamination, and total peace of mind.

After all, in today’s world of strict regulations and consumer awareness, the brands that thrive are the ones that prioritize food safety, innovation, and trust.

FAQs

What can interfere with a metal detector’s accuracy?

Several factors can impact how well a metal detector performs, such as:

Product temperature or moisture

Metalized or foil packaging

Vibration or electrical noise in automated production systems

What are the main types of metal detectors used in food manufacturing?

In the food industry, several metal detectors are available depending on the product type:

Conveyor metal detectors – for packaged or boxed goods

Pipeline detectors – for sauces or liquids

Free-fall detectors – for powders or granules

What makes the best metal detector for foil packaging?

The best metal detector for foil-packaged foods combines multi-frequency detection, digital signal processing, and high sensitivity. Look for features such as:

User-friendly metal detector with color display

Waterproof design for hygiene

Integration with automated production systems

Compliance with HACCP and other food safety plans