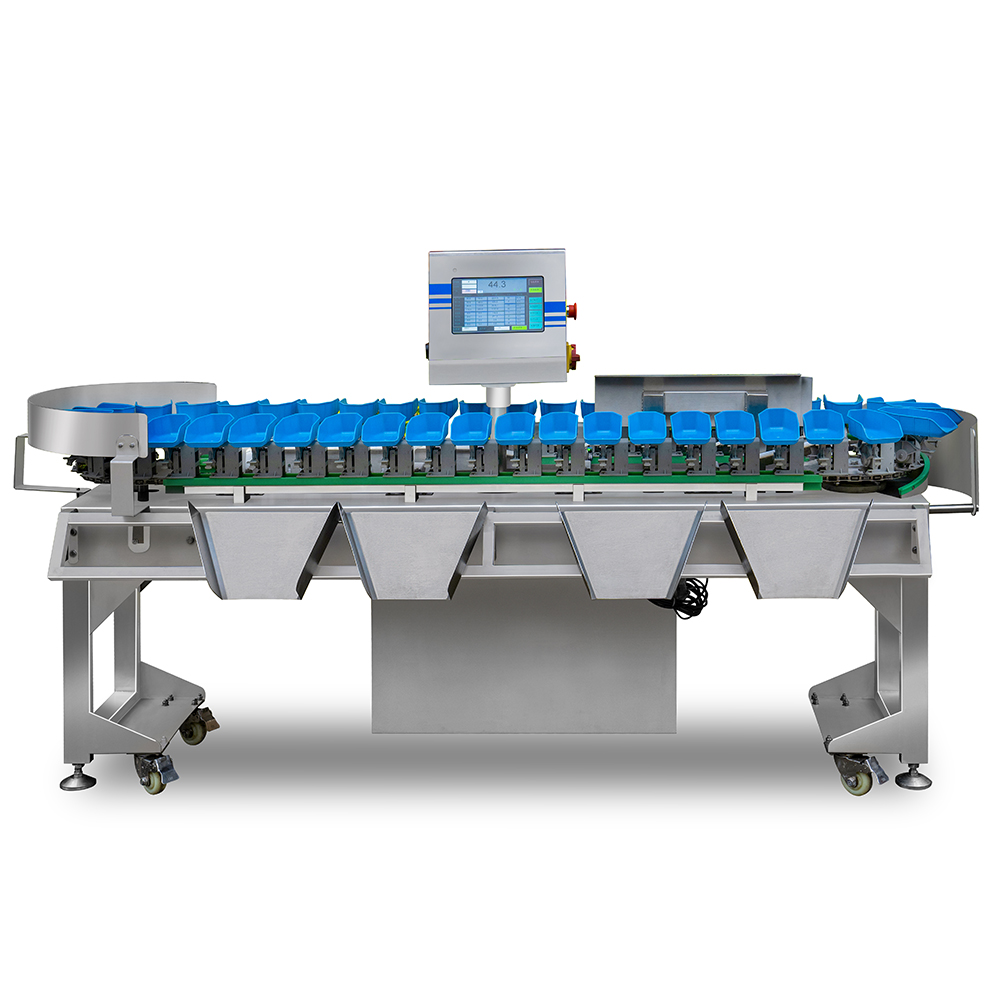

As products (lobster, shrimp, crab and octopus, etc) with different weights and sizes, it is a big challenge for weight grading. How to weigh and sort efficiently the products on the basis of ensuring the integrity of the products is important for weight grader manufacturers.

- Easyweigh offers different kinds of weight sorting machine for bulk or packaged meat products.

- The hygienic design of our weight sorter is easy for daily cleaning.

- The operation of Easyweigh weight grader is easy and user-friendly.