Weighing and detecting in the beverage industry (wine, milk, juice, packaged coffee) ensures product quality and safety. The use of dynamic checkweighers helps maintain consistent beverage quantities in each package, reducing waste and costs.

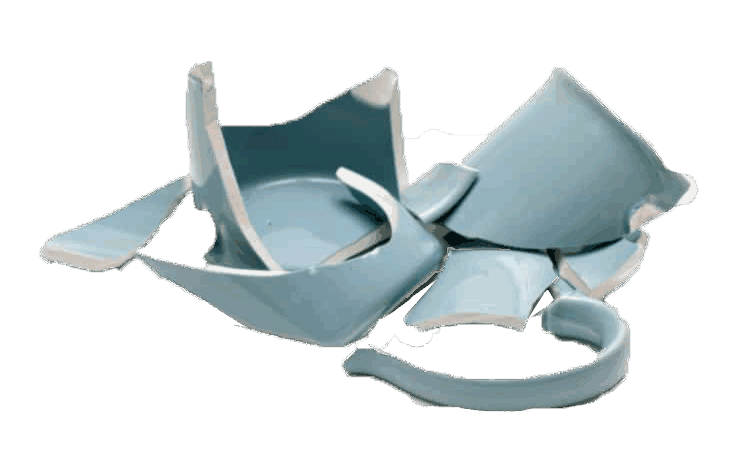

Additionally, food X-ray inspection systems and metal detectors are crucial in identifying and eliminating contaminants, such as glass, stone, or metal fragments, safeguarding consumer health, and maintaining high-quality standards.

Wine

Milk

Juice

Coffee