introduction

Optical sorting machines have been widely used in all kinds of food production lines. During food production, reducing food waste is not only environmentally friendly, but also costs companies less and supports sustainable development goals. A good solution to drive the transformation is the use of optical sorting machines. These sorting machines with advanced technology are changing the way food is processed, graded, and sorted. They make production cleaner, faster, and more productive.

What Are Optical Sorting Machines?

Optical sorting machines are automated systems that use camera vision inspection systems, CCD industrial cameras, image processing technology and sensors to identify and separate items based on size, color, shape, or composition. These visual sorting machines are commonly used in the food industry to remove defective items or foreign materials. For instance, a tomato separator machine can distinguish ripe red tomatoes from green or damaged ones.

The goal is simple. Good products go forward. Bad ones get removed. This reduces waste and boosts product quality. With the rise of the automated food sorting machine market, these machines are now found in nearly every part of the food supply chain.

The Impact of Optical Sorting on Food Waste

Food waste happens at many stages. It can start at the farm and continue through processing, packaging, and retail. Optical sorting machines play a major role in tackling this problem early on.

A vision system for quality inspection can detect tiny defects that human eyes might miss. For example, in a fruit processing line, a fruit sorter with a high-resolution vision system camera can spot bruises, mold, or insect damage instantly. These items are then removed before they affect the rest of the batch.

This prevents large amounts of good food from being discarded just because of a few bad items. As a result, less food is wasted. And the end product is safer and better-looking.

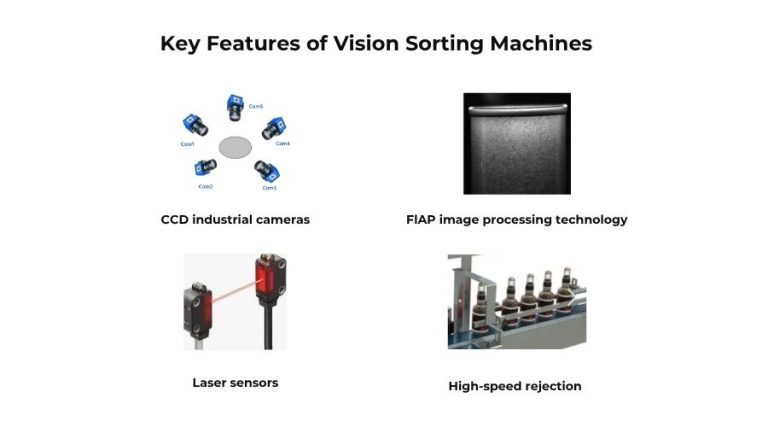

Key Features of Vision Sorting Machines

Why are vision sorting machines so effective? It comes down to their precision and speed. Unlike manual sorting, which can be slow and subjective, machine sorting is fast, reliable, and consistent.

Here are some key features:

Multispectral CCD industrial cameras: These detect subtle differences in color and composition.

Easyweigh independently developed FlAP image processing technology: multi-level algorithm processing, intelligent analysis of fruit shape, wrinkled skin, broken skin, etc.

Laser sensors: They measure density and chemical properties.

High-speed rejection systems: Items are sorted or removed in real time.

Modern vision inspection systems can even be trained using artificial intelligence. Over time, they learn what defects look like and improve their detection accuracy. That means fewer errors and less waste.

Real-World Applications in Food Production

Let’s take a closer look at how optical sorting machines are used in real food production settings.

Fruits and Vegetables

In tomato processing, a tomato separator machine quickly sorts good tomatoes from unripe or damaged ones. This ensures that only the best tomatoes go into sauces or canned products.

In apple packing houses, a fruit sorter equipped with a camera vision inspection system can detect rot, bruises, or skin blemishes. This protects the brand’s image and reduces rejected shipments.

Nuts and Grains

Sorting peanuts? A vision sorting machine can remove shells, stones, and other debris. In grain processing, optical sorting machines remove discolored or spoiled kernels, ensuring only premium grains are packed.

Packaged Foods

Some vision inspection systems are used after food is packaged. They verify that labels are correct, seals are intact, and packaging is clean. This prevents waste at the retail stage by ensuring every product meets quality standards.

Businesses that invest in optical sorting machines enjoy several benefits:

Less food waste: Detect and remove defects early.

Better quality control: Ensure only good products move forward.

Lower labor costs: Machines work faster and longer than humans.

Data insights: Track defects and improve processes.

The data collected by automated vision inspection systems also helps with traceability and compliance. Companies can use this information to adjust their farming, processing, or packaging practices.

The Future of Optical Sorting in Food Processing

As technology advances, optical sorting machines are becoming smarter. AI and machine learning allow vision system for quality inspection to adapt in real time. They don’t just follow fixed rules. They learn and improve.

This is especially useful in complex environments, such as sorting mixed produce or identifying new types of contaminants. The growing demand in the automated food sorting machine market reflects this trend.

We are also seeing integration with robotics. Some systems now include robotic arms that pick and place items with high precision. This further reduces human error and speeds up production.

Another trend is miniaturization. Smaller vision inspection systems can now be used in compact food processing lines. This opens doors for small and medium enterprises to benefit from the same technology once limited to large factories.

Conclusion: Smarter Sorting for a Better Planet

Waste is one of the biggest challenges in food production. Optical sorting machines offer a smart, scalable way to address this problem. They bring precision, speed, and consistency to the sorting process.

Whether it’s a vision sorting machine, a fruit sorter, or a tomato separator machine, these tools are making a real difference. They cut down on waste. They improve quality. They help businesses grow responsibly.

As the automated food sorting machine market continues to evolve, the future of food processing looks brighter, cleaner, and more efficient than ever.

So, the next time you enjoy a perfect piece of fruit or a flawless tomato sauce, thank the camera vision inspection system working silently behind the scenes.

FAQs

How do food save optical sorting machines?

The faulty and spoiled ones are eliminated early in the production process. Thus, there is less spoilage along with reduced opportunities for a whole batch to get rejected.

Are the visual sorting machines suitable for small food industries?

Yes. Miniaturization and affordability have made vision sorting machines accessible to small- and medium-sized food producers.

What can be inspected by a vision inspection system?

A vision inspection system will inspect color, shape, size, surface defects, and potentially internal defects depending on the technology of the sensor used.