Introduction

Food safety is a duty, not just a slogon. Knowing what physical hazards are in food can make or break your brand, whether you’re managing a high-volume fruit sorting facility, a snack processing line, or a seafood processing factory.

What are three types of hazards that make food unsafe? Experts in food safety say they consist of:

Biological hazards in food (such as parasites, viruses, and bacteria)

Chemical food hazards (like pesticides, cleaning products, or allergens)

Physical hazards in food (foreign objects such as glass, metal fragments, or pieces of bone)

This blog will go into great detail about food physical hazards, including what they are, why they are harmful, and how to avoid them with smart tools like X-ray machines, vision sorting machines.

What Are Physical Hazards in Food?

Physical hazards in food refer to any foreign object that could cause injury or illness when consumed. These include:

Metal fragments from broken machinery

Bone shards left in processed meat or fish

Pieces of glass from light fixtures or packaging

Stones, plastics, or wood chips

| Hazard Type | Example | Risk |

|---|---|---|

| Metal | Machine screws, blades Tooth chips | lacerations |

| Bone | Fishbone in fillet, Wish bone | Choking, throat puncture |

| Glass | Broken jars, light fixtures | Internal bleeding |

| Plastic | Packaging shards | Blockages, choking |

When customers bite into a contaminated product, the consequences go beyond negative reviews—they affect health, trust, and compliance. That’s why identifying and preventing hazardous foods before they ship is critical.

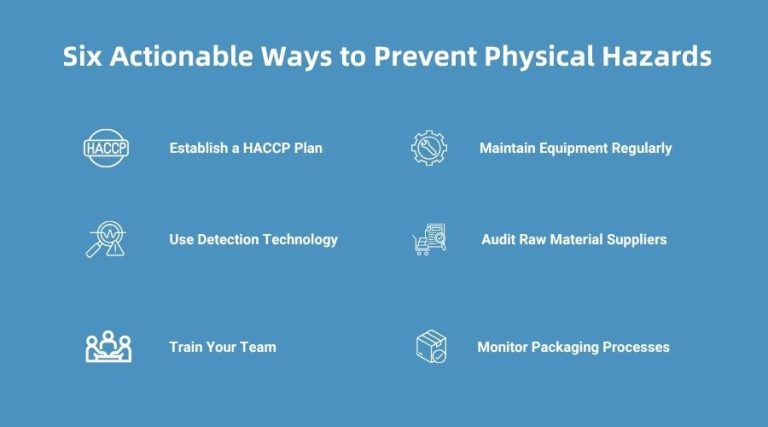

How to Prevent Physical Hazards in Food

So, now that we understand what are physical hazards in food, how do we keep them out of the supply chain?

Here are six clear, actionable ways to prevent physical hazards in food production:

Establish a HACCP Plan

A Hazard Analysis Critical Control Point (HACCP) food safety plan identifies risks and sets control points at key steps in production. It’s not optional—it’s a legal requirement in many countries.

Mapping where physical food hazards can enter the process is the first step toward prevention.

Use Detection Technology

Let’s be honest—potentially hazardous foods like boned meat, shelled nuts, or processed snacks can easily hide physical contaminants. That’s why relying solely on visual checks or manual sorting is risky.

Instead, industry leaders now use:

X-ray inspection systems to detect glass, stone, or metal fragments in packaged products, even in aluminum foil packaging

Vision sorting machines to spot foreign objects, shape defects, or color abnormalities in bulk items

Metal detectors that screen for stainless steel, ferrous, and non-ferrous metals

For example, an advanced vision system camera can detect foreign plastic in a pile of white mushrooms or a hidden fishbone in a conveyor of frozen fillets.

The use of automated food sorting machines has grown dramatically in the last five years, especially in industries dealing with hazardous foods like seafood, frozen meals, and processed meat.

Train Your Team

Do your employees know what are three types of hazards that make food unsafe? Make sure they can answer that. Regular training helps staff detect and report physical hazards early.

Include real examples of physical food hazards they may encounter.

Maintain Equipment Regularly

Many physical hazards in food come from damaged or aging equipment—broken seals, loose screws, or worn parts. Implement a preventive maintenance schedule and inspect machines daily.

Don’t wait until something breaks to take action.

Audit Raw Material Suppliers

Check for hazardous foods before they reach your facility. Stones in grains, shells in seafood, or bones in ground meat can all come from upstream.

Audit your suppliers. Require them to share their hazard analysis control point policies.

Monitor Packaging Processes

Packaging machines move fast. When something breaks, like a plastic tray or glass jar, fragments may contaminate hundreds of items before anyone notices.

Set up inspection checkpoints at the packaging stage to catch physical hazards before distribution.

Common Physical Food Hazards Examples in Different Industries

Every food industry faces different threats when it comes to physical hazards in food. These threats often depend on the nature of the raw materials, production environments, and packaging processes. Below, we’ll look at real examples of physical food hazards and how to prevent them.

Meat Processing: Hard Bone and Metal Fragments

In meat processing line, especially secondly processing products , small bone are mixed easily. These physical hazards in food may be small, but they pose serious choking risks to consumers.

Another threat? Metal fragments from grinders, saws, or broken blades. These can be extremely dangerous and difficult to detect without the help of metal detectors or X-ray inspection systems.

Using a X-ray machine alone isn’t enough here—you need vision inspection machine to achieve more comprehensive detecting results

Seafood Industry: Shell Pieces and Plastic

When processing shellfish or filleting fish, shell pieces, fish bones, and broken equipment parts can easily make their way into the final product. These are all classic physical food hazards examples.

What’s worse, seafood is often vacuum-packed or wrapped in film—making plastic fragments another common risk. Investing in high-sensitivity X-ray systems is key to catching non-metal contaminants that might slip past traditional detection methods.

Snacks and Bakery: Stones and Hard Plastics

In the snacks industry—especially when working with nuts, grains, or dried fruits—stones, sticks, and even metal clips from packaging machinery are all potential physical hazards in food.

Crackers and biscuits may also pick up hard plastic fragments during high-speed packaging. One broken tray or worn-out machine part can lead to widespread contamination. That’s why preventive maintenance and real-time inspection are non-negotiable.

Ready-to-Eat Meals: Glass and Bone Shards

Glass shards from broken jars, bone pieces in cooked meats, and plastic bits from packaging automation are all examples of hazardous foods in the ready meal industry.

Because these meals go through multiple steps—cooking, freezing, sealing, and reheating—they need constant inspection throughout the process.

By implementing Hazard Analysis Control Point (HACCP) checkpoints at every major step, manufacturers can catch problems early and reduce risk exposure.

Choosing the Right Hazard Detection Equipment

When designing your hazard control system, it’s important to choose equipment tailored to your product and risks. Let’s compare some popular options:

| Technology | Best For | Strengths |

|---|---|---|

| Vision Sorting Machine | Surface defects, color, plastic | Non-contact, fast, visual + AI detection |

| X-Ray Inspection | Bone, glass, metal, rubber | Detects internal contaminants, even in packaging |

| Metal Detector | Ferrous, non-ferrous metals | Low cost, good for bulk or packaged products |

Combining these technologies allows manufacturers to create a comprehensive HACCP food safety strategy that covers a wide range of physical food hazards.

Conclusion

Building a Strong Defense Against Physical Hazards in Food Preventing physical hazards in food is not optional—it’s a vital responsibility that protects consumers and preserves your brand’s integrity. Whether you’re a small food producer or a global manufacturer, the threats posed by physical food hazards like bones, glass, plastics, or metal fragments are real and dangerous.

Understanding the three types of food hazards—biological hazards, chemical hazards, and physical hazards in food—allows you to take targeted action. While good hygiene and cooking practices help prevent biological hazards in food, advanced inspection technology is critical for detecting physical food hazards examples that are often invisible to the naked eye.

FAQs

What are physical hazards in food?

Any foreign objects or materials which might cause injury or harm to a consumer, are physical hazards in food. Common examples may include glass, metal fragments, small bone, plastic, etc. These hazards generally arise from malfunctioning equipment, poor handling of the food, or improper food processing techniques.

How do I prevent physical hazards in the food process?

To prevent physical hazards in food contamination, build HACCP procedures, use equipment such as metal detectors, vision sorting machines, and X-ray systems in production line. Training employees can identify the presence of foreign objects at an early stage in the production, thus avoiding contamination.

Physical examples of food hazards?

A vision inspection system will inspect The first category of hazard is anything not supposed to be present in food but contaminates it. Examples that fish with bone, glass pieces in jam, plastic foreign objects in packaged products, and even metal from machinery! These contaminants, if undetected and undeterred, would pose grave health hazards.color, shape, size, surface defects, and potentially internal defects depending on the technology of the sensor used.