Introduction

Food safety is the backbone of public health. It ensures that our food is free from contamination and safe for consumption. From production to plate, food safety practices protect consumers and preserve brand reputation. In today’s global food supply chain, one unsafe product can cause a ripple effect of health and economic problems. But what is food safety, and why is it so important in modern food systems?

What Is Food Safety?

Food safety refers to handling, preparing, and storing food in ways that prevent foodborne illnesses. It includes everything from hygiene practices in food processing plants to proper labeling on packaging. Following food safety regulations is not optional—it is essential for protecting public health.

Hazard Analysis Critical Control Point (HACCP) food safety systems are a global standard. They identify potential hazards and define control measures. These systems reduce the risk of contamination at every stage of the food supply chain.

Key Points:

Food safety hazards include biological, chemical, and physical contaminants.

A strong food safety compliance system reduces the chance of foodborne illnesses.

The HACCP food safety model is a proven method for controlling risks.

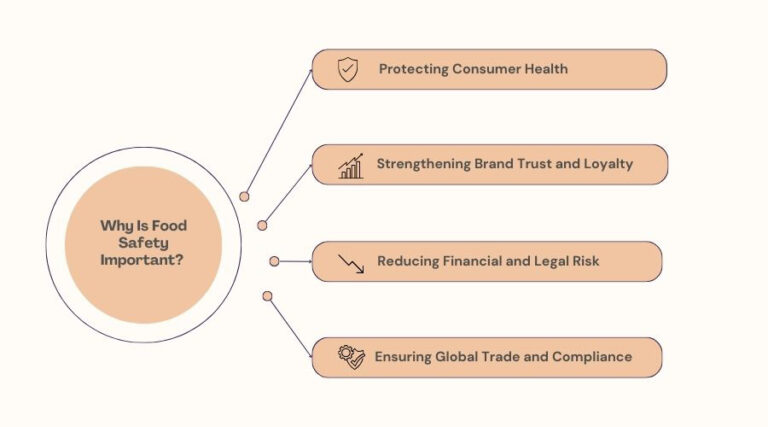

Why Is Food Safety Important?

Food safety is the cornerstone of public health, consumer confidence, and a sustainable food industry. When food is handled, processed, and distributed with safety in mind, it prevents illnesses, reduces recalls, and protects both people and brands. In a world where supply chains stretch across continents, one misstep can trigger widespread health crises and financial fallout.

Failing to maintain food safety compliance can lead to more than just public health risks. It can result in costly recalls, loss of consumer trust, and severe legal penalties. Food safety is essential at every level, from farms and factories to packaging and distribution.

Proactive companies understand this. They adopt global standards like Hazard Analysis Critical Control Point (HACCP) and use X-ray inspection systems and metal detectors—to detect threats before products reach the market.

Protecting Consumer Health

Safe food prevents foodborne illnesses caused by pathogens, allergens, or foreign objects. By following strict food safety protocols, companies reduce public health risks and protect consumer health.

Strengthening Brand Trust and Loyalty

Customers expect safety. Businesses that consistently deliver safe products earn long-term loyalty and differentiate themselves from competitors.

Reducing Financial and Legal Risk

Product recalls, lawsuits, and regulatory fines are costly. Strong food safety systems help prevent these events and protect the bottom line.

Ensuring Global Trade and Compliance

International markets demand compliance with rigorous food safety regulations. Companies must meet these standards to access global opportunities and avoid trade barriers.

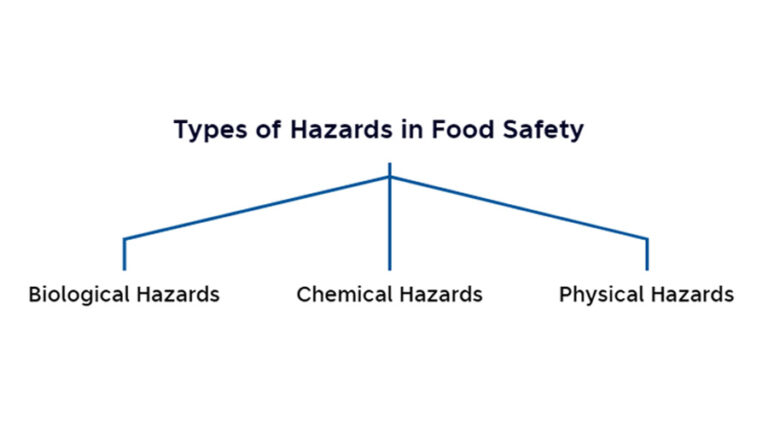

Types of Hazards in Food Safety and How to Prevent Them

Understanding the types of hazards in food is the first step toward prevention. There are three main categories:

Biological Hazards: Bacteria, viruses, and parasites. These can cause serious health problems.

Chemical Hazards: Contamination from pesticides, cleaning agents, or additives.

Physical Hazards: Foreign objects like glass, metal, aluminum foil or bone fragments.

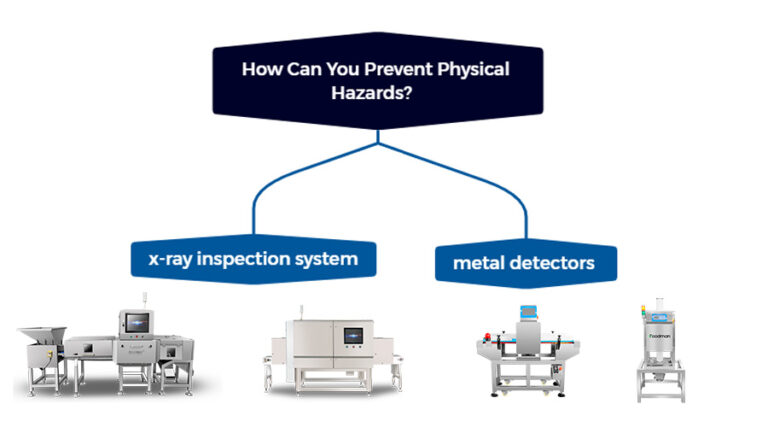

How Can You Prevent Physical Hazards?

To answer the question, “how can you prevent physical hazards?” you must invest in technology and staff training. One effective method is using an x-ray inspection system. These machines can detect even the smallest contaminants. They are especially useful for spotting a physical hazard in food like bone fragments or metal pieces.

Metal detectors are another tool. They scan for metallic objects in packaged goods. But for more accurate detection of various contaminants, x-ray inspection machines are superior. For instance, the Bonexray x-ray inspection system specializes in identifying bone fragments in meat products.

Prevention Tips:

Conduct regular hazard and critical control points reviews.

Invest in both metal detectors and X-ray inspection machine technology.

Train staff to identify and respond to potential hazards.

Preventing poor food safety starts with culture. A company committed to food safety creates a ripple effect of compliance throughout the organization. So what is the best way to prevent poor food safety?

Start with clear food safety compliance protocols. Enforce them with accountability. Everyone in the organization—from executives to floor workers—must understand their role in keeping food safe.

Proven Methods:

Implement a robust HACCP food safety system.

Use a reliable food safety inspection schedule.

Regularly update your hazard and critical control points.

Monitor equipment like metal detectors and x-ray inspection machines.

Technology plays a vital role. For example, installing an x-ray inspection system or Bone xray solution provides an extra layer of safety. These tools are important for bone-in meat, seafood, and ready-to-eat products industries.

Food safety regulations are laws and guidelines set by national and international agencies. Their goal is to protect consumers and ensure fair trade. These rules shape everything from food labeling to food safety inspection procedures.

Companies that ignore these rules risk more than just fines. They also risk their reputation. Food safety compliance is a competitive advantage. Businesses that go beyond minimum standards often earn customer trust and brand loyalty.

Global and Local Examples:

The FDA in the United States enforces the Food Safety Modernization Act (FSMA).

The European Union has strict traceability and labeling requirements.

China’s food safety regulations have become more stringent after several high-profile scandals.

Adhering to regulations means performing regular hazard analysis. It also involves using advanced equipment like x-ray inspection systems and metal detectors to meet safety standards.

Why X-Ray Inspection Systems and Metal Detectors Are Essential to Food Safety?

Modern technology has transformed food safety protocols. X-ray inspection and metal detector systems are now essential tools in detecting contaminants and ensuring food safety compliance.

An x-ray inspection machine works by scanning products for density differences. This allows it to detect non-metallic objects like glass, bone, or plastic. The Bonexray x-ray inspection system is a leader in this field, offering high-resolution imaging and fast processing times.

Metal detectors are simpler but still important. They detect ferrous and non-ferrous metals. They are often used earlier in the production line, while x-ray inspection systems are used at final stages for more comprehensive checks.

Advantages:

X-ray inspection systems can identify multiple types of food safety hazards.

Bonexray solutions are ideal for detecting physical hazard in food such as bones or stones.

Metal detectors provide a cost-effective way to catch metallic contaminants.

| Tool | Detects | Best Use |

|---|---|---|

| X-ray inspection system | Bone, glass, rubber, stone | Final product detect |

| Metal detector | Steel, aluminum, wires | Raw or bulk materials |

Conclusion

Food safety is not just a government requirement. It is a moral and professional obligation. From understanding the types of hazards to knowing what is the best way to prevent poor food safety, the path to safety is clear.

Using advanced tools like metal detectors and x-ray inspection machines (including Bonexray) is a smart investment. Following HACCP food safety principles and meeting food safety regulations will not only ensure compliance but also build trust.

In a world where one slip can ruin a brand, food safety should be every company’s top priority. It’s time to take action, invest in technology, train staff, and make food safety part of your company culture.

Food safety is important because it protects public health, prevents foodborne illness, ensures regulatory compliance, and supports a trustworthy food system.

The best approach is to follow proper hygiene and temperature control guidelines and implement systems like HACCP to identify and manage hazards.

HACCP (Hazard Analysis Critical Control Points) is a food safety system that identifies hazards in food production and outlines procedures to prevent them.