How X-Ray and Grading Technology Are Transforming Meat Processing

Discover how advanced technology is transforming meat operations, from contamination detection to fat analysis and weight grading.

Table of Contents

Introduction to Meat Processing Challenges

Why Precision Matters in Meat Processing

In meat processing, precision is everything. One small mistake can compromise safety, waste product, or even shut down production. With food safety standards rising and customer expectations increasing, processors face mounting pressure to deliver consistent, high-quality meat every time. Let’s take a closer look at the challenges they face:

Foreign object contamination

From tiny metal fragments to plastic and bone, unwanted materials often enter production lines. These contaminants are not only dangerous but also expensive, leading to recalls, fines, and damaged reputations.

Inconsistent fat content

Too much or too little fat in a batch can ruin quality, affect flavor, and result in failed inspections. It also causes waste, which can affect your bottom line.

Bone residue in boneless products

Even microscopic bone fragments in poultry or pork can lead to rejected shipments, especially in exports.

Manual grading inefficiencies

It’s slow. It’s inconsistent. It can’t keep up with high-volume demand. Human error is inevitable, and results vary from shift to shift.

These aren’t small issues—they’re industry-wide pain points. So, what’s the solution? Today’s leading processors are turning to automated sorting systems—a blend of optical sorting equipment, x-ray inspection and fat analysis. These systems detect, analyze, and sort meat with incredible speed and accuracy. With machine sorting and real-time decision-making. Every meat product is safer. Every line runs faster.

Want to see how this technology works in real operations?

From Farm to Fork: How X-Ray Inspection Systems are Revolutionizing Meat Safety

Maintaining stringent safety measures is essential from farm to fork, and X-ray inspection systems have become a game-changer in the meat processing industry. Click here ➜

Detection: Eliminating Metal, Glass, Bone in Ground & Emulsified Meat

Contaminants in ground and emulsified meats are notoriously difficult to detect. Once the meat is minced, how do you find a hidden shard of metal—or a splinter of bone or glass? You can’t rely on manual inspection. The risk is too high.

This is where the Pipeline X-Ray Inspection System comes in. Designed specifically for high-volume meat processors, this x-ray machine scans product in real time—before it reaches the filler or packaging stage. It’s a powerful tool for industries producing sausages, pâté, or ground beef.

Foodman Pipeline X-Ray Inspection system

Equipped with IP69K protection, this x-ray inspection system withstands high-pressure washdowns without compromising performance. It fits directly into your continuous flow processing line and detects even the smallest contaminants using advanced x-ray equipment.

What makes it different? Speed, accuracy, and hygiene. Unlike traditional x-ray machines, the Pipeline X-Ray is purpose-built for inline inspection of emulsified meat products, reducing waste and ensuring product integrity.

Ensuring Boneless Precision in Poultry and Pork Cuts

Tiny bone fragments in meat products can cause big problems. They’re hard to see, tough to catch—and impossible to ignore. In poultry and pork cuts, even a 0.2mm shard can lead to product recalls, customer complaints, or export rejection.

How can you find what’s nearly invisible?

Foodman Dual Energy X-Ray Inspection For Bones

Enter the Foodman Dual Energy X-Ray Inspection For Bones—a breakthrough in modern x-ray inspection. Unlike standard x-ray machines, this system uses dual-energy technology to detect low-density materials like soft bone from higher-density materials such as hard bone.

It’s not just smart. It’s incredibly precise.

By analyzing different energy absorption levels, this advanced x-ray equipment can detect and classify bone fragments hidden deep in processed meats. From fan bones in poultry to rib tips and spinal pieces in pork, the bone xray system delivers detection accuracy as high as 98%—even at high line speeds.

Fat Analysis: Real-Time Fat-to-Lean Ratio

In meat processing, fat content isn’t just a quality metric—it’s a profit driver. When fat levels vary, everything is affected: product consistency, pricing accuracy, and compliance with labeling standards. A few percentage points off? That can mean thousands lost in giveaway or fines.

So, how do you ensure every batch meets your exact lean specifications?

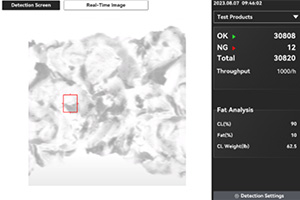

Foodman Fat Analysis X-Ray Inspection System

With Easyweigh’s real-time Fat Analysis powered by precision x-ray inspection systems, you get actionable data, right on the line. These advanced x-ray machines scan pork trim, beef blends, and other emulsified meats, identifying fat and lean areas based on density differences.

✅ Key Advantages of Fat Analysis:

- Accurate to ±1%

- Live fat-to-lean ratio monitoring

- Compatible with automated sorting and batching

Automated Sorting: Weight for Cut Consistency

In meat processing, precision isn’t optional—it’s essential. Whether you’re portioning tenderloin steaks or sorting pork belly in bulk, consistency in weight equals consistency in quality. But how do you achieve that at scale?

With Easyweigh’s advanced weight sorting machines, you bring speed, accuracy, and automation to every cut.

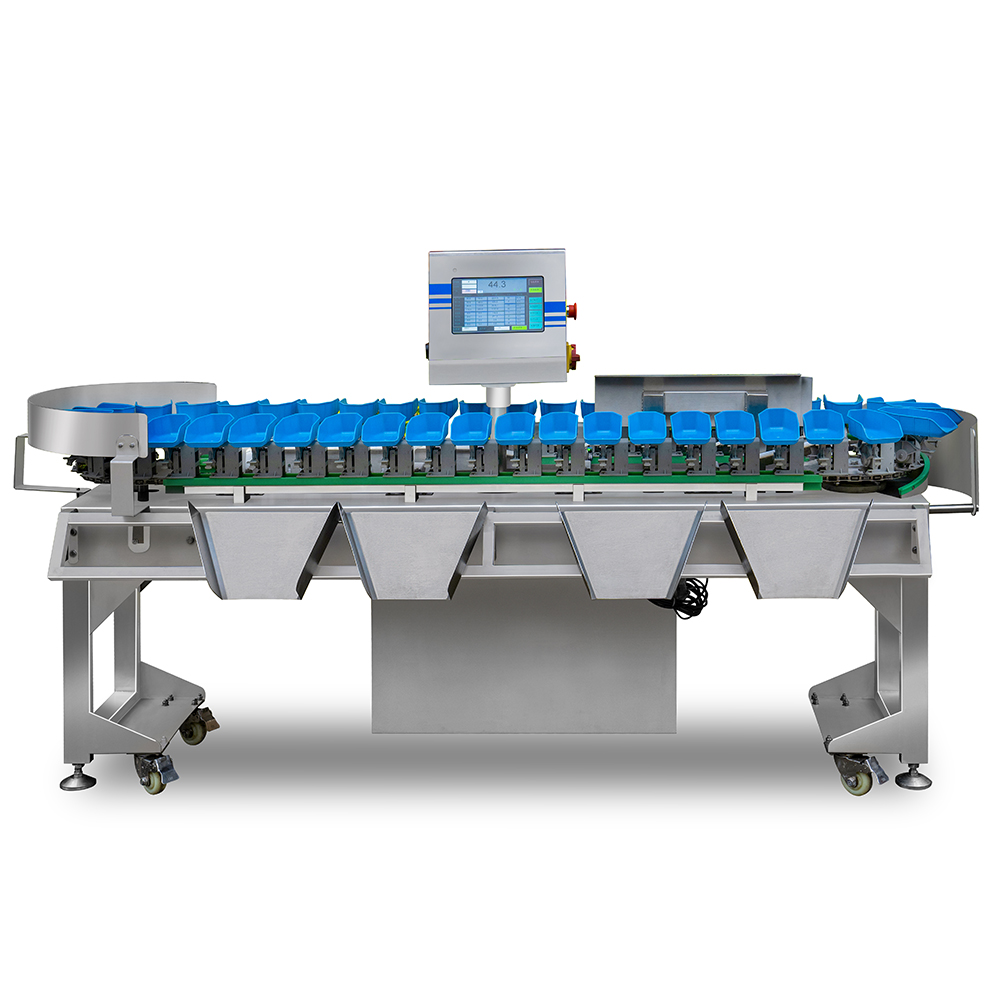

Rotating Trays Weight Grader

Handling delicate cuts like steaks and ribs? This Weight Grader is built for care. Using smooth rotating trays, it ensures gentle machine sorting without damaging the product. Want flexible grading options? You’ve got them—set your weight thresholds, and let the automated sorting system do the rest. It’s precise. It’s customizable. It’s built to handle the most sticky meat products.

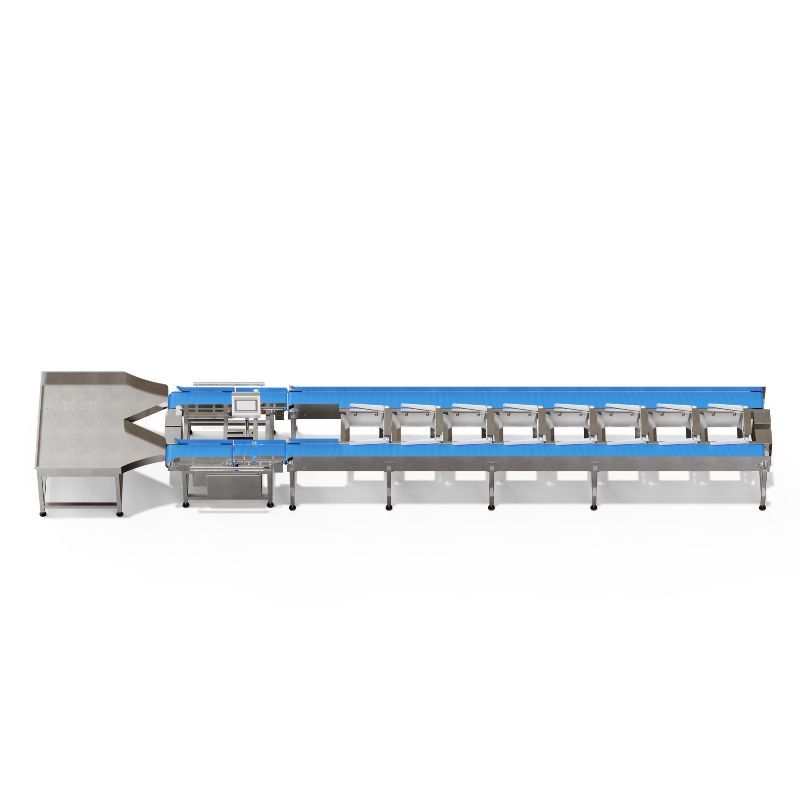

Dual Lane Weight Grader

When speed matters, the Dual Lane Weight Grader delivers. Think high-throughput. Think double the lanes, double the output. Ideal for bone-in cuts, whole pieces, and pork bellies, this auto sorting machine processes large volumes with pinpoint weight accuracy.

Our sorting systems optimize efficiency and reduce waste every time.

Case Study

How a Pork Processor Boosted Yield by 25%

Challenge

How do you maintain consistency in fat content while reducing labor errors in a fast-paced meat processing environment? That was the challenge a leading pork processor faced. Fat variability led to frequent rework, while manual grading resulted in inconsistent product quality and rising QA complaints.

Solution

Results:

FAQs

A weight sorting machine automatically classifies meat cuts based on weight. This matters more than you might think. A weight sorting machine automatically classifies meat cuts based on weight. Precision here means pricing accuracy, consistent packaging, and reduced waste. With Easyweigh’s Weight Grader, you get exact sorting that’s fast, gentle, and fully automated.

X-ray inspection systems scan every product in real time—exposing metal, glass, rubber, and even tiny bone fragments. The system adapts to ground, whole, or packaged meat, helping processors meet strict safety and export standards.

Absolutely. Our bone x-ray solution, powered by dual-energy imaging, can detect bones as small as 0.2 mm. Whether it’s poultry or pork, this technology ensures boneless precision—protecting both your brand and your customers.

Share This Post