Smart Seafood Solutions: Sorting, Detecting, and Weighing for Peak Performance

Transform your seafood sorting facility with automated grading, weighing, and contaminant detection.

Table of Contents

Introduction: The Future of Seafood Sorting, Detection, and Weighing

In today’s fast-moving seafood industry, processors encounter a wide range of challenges. From cold shrimp sorting inconsistencies to hidden bones or traces of metal, quality threats are everywhere. Can outdated manual systems keep up with these demands? Hardly.

Traditional methods and aging detection tools fall short in a market that demands precision, speed, and global compliance. The result? Risky inefficiencies, inconsistent quality, and lost yield.

That’s where Easyweigh comes in.

We deliver a complete, intelligent solution for seafood processing. Our lineup includes smart sorting machines, advanced x-ray inspection systems, precise checkweighers, and high-throughput weight graders. Each system is engineered for performance. Together, they streamline production, enhance food safety, and increase profitability.

Want to stay competitive? Our solutions are built not just for today’s seafood processors—but for tomorrow’s leaders.

Seafood Processing Challenges

- Inconsistent cold shrimp sorting causing product giveaway and rework.

- Undetected contaminants like bones, shells, and metal fragments leading to recalls.

- Slow manual grading that reduces throughput and quality control.

- Harsh marine conditions damaging conventional sorting equipment.

Meeting these challenges requires automated sorting machines, x-ray machines, and checkweighers engineered specifically for seafood environments.

Contaminant Detection Equipment

Foodman X-Ray Inspection System

- The Foodman x-ray inspection system identifies microscopic contaminants in seafood such as fish fillets, shrimp, squid, and shellfish.

- Detects glass, shells, bones, stones, and metal particles.

- Designed for moist, saltwater-heavy seafood processing environments.

- Integrates seamlessly with downstream sorting equipment

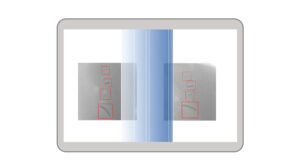

Contaminant of the Foodman x-ray inspection system

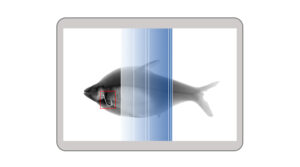

Foodman X-Ray Inspection System For Fishbone

Using advanced imaging, this dual energy x-ray machine detects even low-density fish bones invisible to regular scanners. Ideal for export-grade seafood.

Featuring ultra-high-resolution imaging and TDI technology, the system provides detailed images for accurate fishbone identification.

Foodman’s proprietary FIAP image processing technology optimizes fishbone identification.

Comparison of imaging between X-ray machine VS. fishbone X-ray machine

Metal Detectors for Seafood Safety

Ensure your seafood products are free from harmful metallic contaminants with Metal Detector for Aluminum Foil Packaged Products. These metal detector systems are designed to handle foil packaging of seafood products.

Detects stainless steel, ferrous, and non-ferrous metals

Ideal for inline inspection before or after packaging

Perfect for integration with canned salmon and canned sardines

Grading and Sorting Equipment

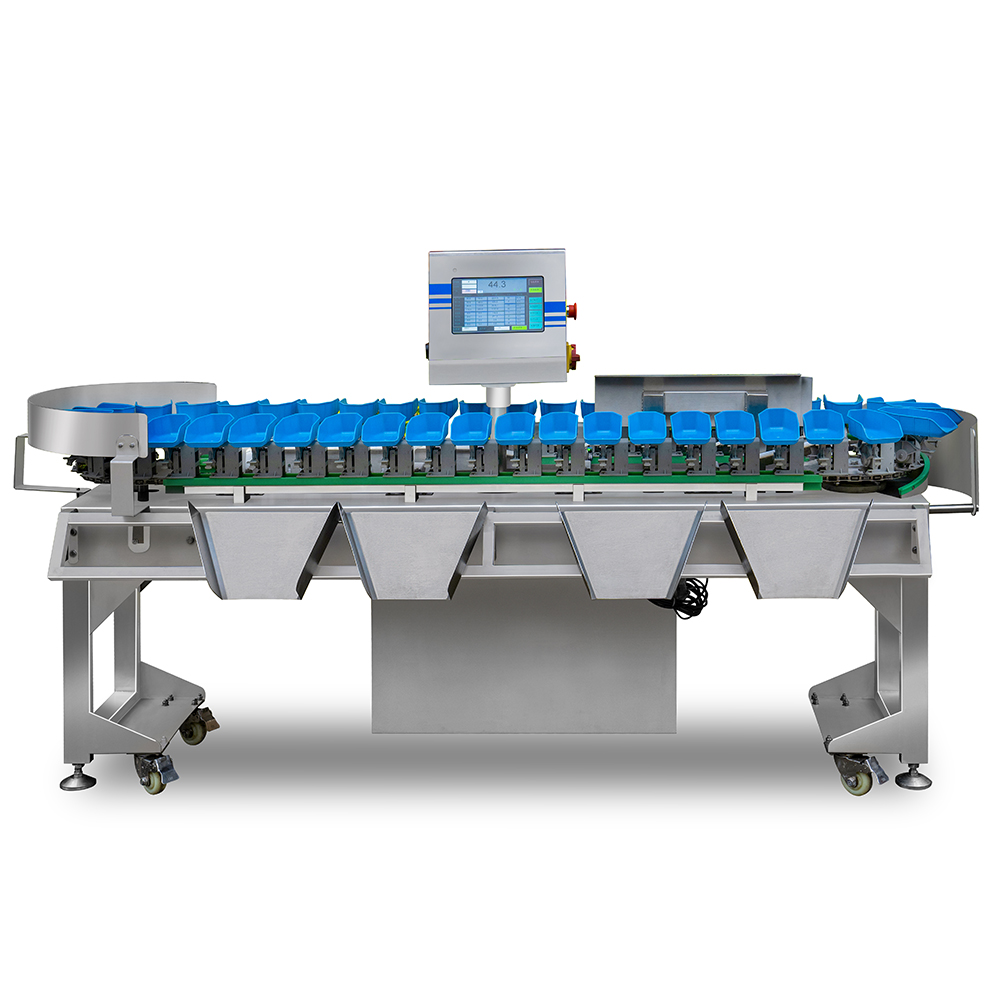

Rotating Trays Weight Grader

Ideal for delicate products, this weight grader uses gentle rotating trays to maintain product integrity while providing accurate sorting.

- Perfect for sushi-grade tuna, scallops, prawns, etc.

- Up to 16 weight categories.

- Minimal damage to soft seafood products.

Seafood suitable for sorting

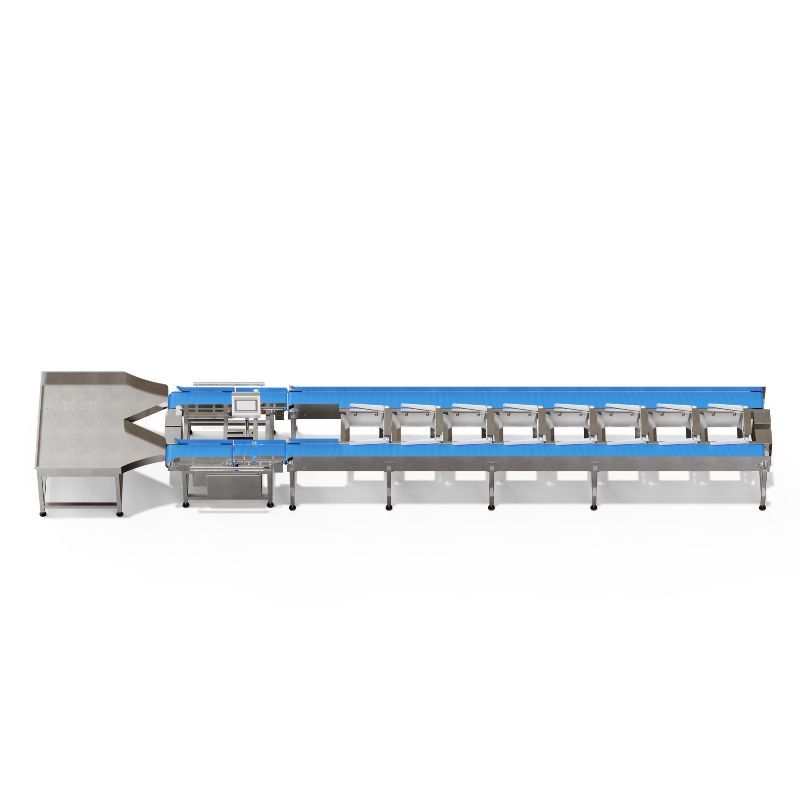

Dual Lane Weight Grader

Handle large volumes of squid, tilapia, and fish steaks with the Dual Lane Weight Grader—built to double your throughput.

- Dual parallel lines operate simultaneously

- Reduces bottlenecks in bulk seafood sorting

- Quick cleaning for hygiene compliance

Easyweigh’s grading and sorting machines empower seafood processors to handle everything from cold shrimp and scallops to bulk fish steaks with accuracy and efficiency. Whether you need precision portioning, gentle handling for delicate seafood, or high-speed bulk grading, our equipment is built to optimize your seafood line and reduce manual labor.

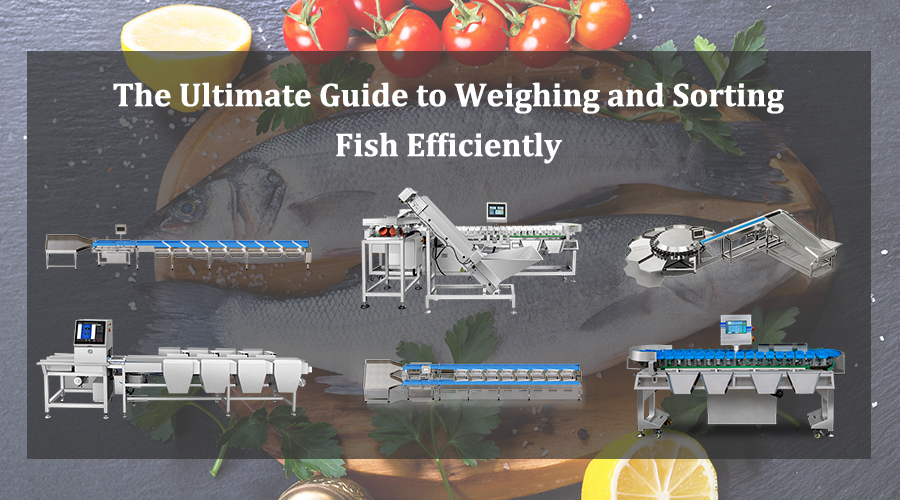

The Ultimate Guide to Weighing and Sorting Fish Efficiently

Consistently grouping fish and food products by size and weight helps producers meet customer expectations, comply with regulations, and reduce waste.Click here ➜

Case Study: Boosting Throughput and Quality

How an Asian Seafood Plant Achieved +28% Throughput with Easyweigh

Challenge

The XX Asian Seafood Plant has received frequent complaints regarding shell fragments, inaccurate weights, and inconsistent shrimp grades.

Solution

Additional Highlights

Results:

Conclusion

Easyweigh empowers seafood processors with industry-best equipment: advanced x-ray inspection systems, high-sensitivity metal detectors, intelligent sorting machines, and robust checkweighers.

Our solutions help seafood facilities increase yield, improve safety, and future-proof production lines. From cold shrimp sorting to fish bone detection, Easyweigh delivers the technology that moves your business forward.

FAQs

X-ray machines can detect shells, glass, metal fragments, bones, and even stones in seafood products.

Absolutely. Our IP66 X-ray machine are specifically built for moist environments like seafood detecting facilities.

It captures subtle differences in density to detect soft, low-density bones standard systems miss.

Share This Post