Introduction

The GULFOOD MANUFACTURING 2025 exhibition, held at the Dubai World Trade Centre from November 4-6, 2025. As for the Easyweigh and Foodman teams, that was a remarkable event. It is one of the global food processing and packaging industry’s premier trade show.

The exhibition provided a great opportunity to showcase our detection and sorting solutions for the food production sector. Attendees were treated to a firsthand look at some of the latest innovations in sorting machines, X-ray inspection machines, checkweighers, and metal detectors. Technologies that are revolutionizing food safety, quality control, and operational efficiency. Let’s remind all the highlights in the exhibition.

From intricate X-ray machines to precision checkweighing machines designed for food production lines, Easyweigh and Foodman’s team at the event highlighted their commitment to providing world-class solutions for the food manufacturing sector.

A Glimpse into GULFOOD MANUFACTURING 2025: A Hub of Innovation

GULFOOD MANUFACTURING is known for attracting professionals from all corners of the food processing and packaging world, making it the perfect platform for showcasing the latest in food safety equipment, quality assurance technologies, and processing machinery.

This year, Easyweigh and Foodman took center stage by unveiling their state-of-the-art sorting machines and inspection technologies, which garnered significant attention for their role in improving food safety, efficiency, and product quality across the food manufacturing industry.

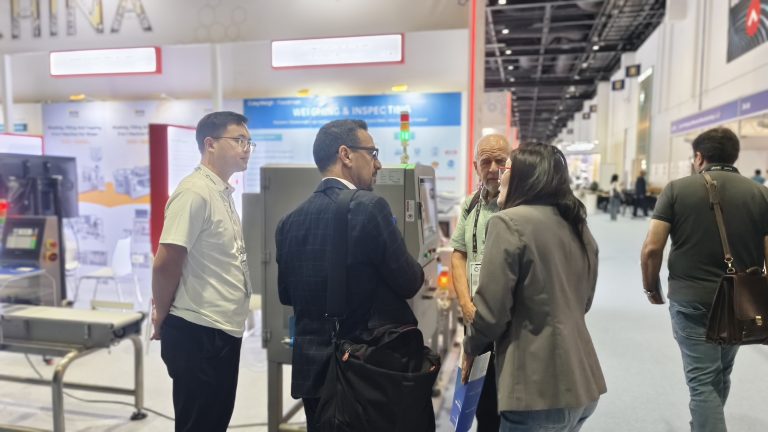

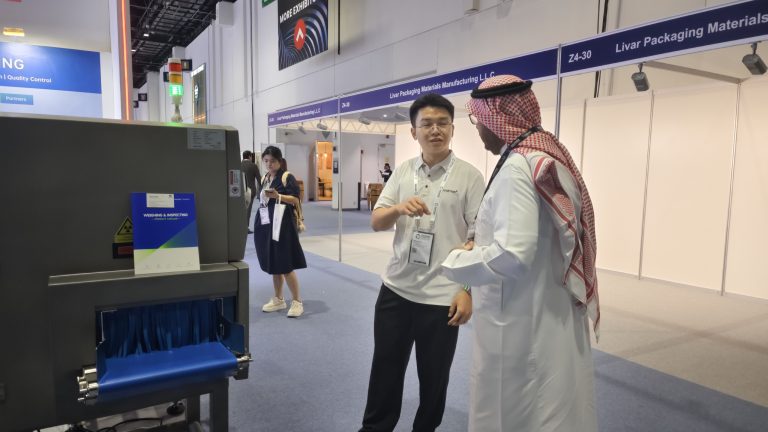

For three action-packed days, the Easyweigh and Foodman booths were buzzing with activity as attendees explored firsthand the innovative capabilities of their metal detectors, X-ray systems, and sorting machines. Visitors were able to see live demonstrations of how these advanced machines can sort, inspect, and ensure the highest quality in food products — all while streamlining the production process.

Professional Sorting Technology: Revolutionizing Food Production

At the heart of the Easyweigh and Foodman booths was their sorting machine technology. In today’s fast-paced food manufacturing world, automated sorting systems are key to increasing product sorting efficiency while maintaining high-quality standards. The vision sorting machines showcased at the exhibition impressed with their ability to quickly identify and categorize food products based on size, weight, and even internal quality characteristics like ripeness and defects.

These automatic sorting machines are especially valuable in industries that deal with bulk food products, like fruits, vegetables, meat, and seafood. For instance, poultry sorting was one of the key demonstrations, where Easyweigh’s AI-powered sorting systems accurately sorted pieces by size, weight, and shape. This makes it easier for manufacturers to produce uniform batches, minimize waste, and increase throughput without compromising product quality.

By leveraging optical sorting technology, these machines can assess products in real time, ensuring that only the best quality food makes it to the packaging line. Sorting accuracy was a huge selling point at the exhibition, with visitors witnessing how these systems minimize errors that can occur during manual sorting processes.

Ensuring Food Safety: The Power of X-ray Inspection Systems

Food safety is a top priority for both consumers and manufacturers. That’s why Easyweigh and Foodman placed a strong emphasis on X-ray inspection machines at the event. These high-tech systems are designed to detect contaminants like metal, glass, plastic, and stones that can pose a risk to food safety.

The X-ray inspection systems showcased by Easyweigh are equipped with advanced imaging capabilities that go beyond what traditional metal detectors can achieve. While metal detectors are great for detecting ferrous and non-ferrous metals, X-ray systems are capable of identifying foreign objects that may not be detected through traditional methods.

For example, consider a scenario where a batch of chicken products is being processed. Using X-ray inspection, any hidden contaminants like bones, glass fragments, or other foreign materials can be detected, even if they are inside the meat. This helps manufacturers adhere to food safety regulations and prevents potential recalls or customer complaints due to contaminated products.

Easyweigh’s dual-energy X-ray systems offer an added advantage, as they can differentiate between product and contaminants based on the material’s density, ensuring greater accuracy in identifying potential hazards (such as fishbone, small hard bone).

The Role of Checkweighers in Food Production

Another star of the show was the checkweigher technology from Easyweigh and Foodman. Checkweighers play a vital role in the food industry, ensuring that each product is within the specified weight tolerance. Whether it’s a pack of snacks, a bag of flour, or meat portions, checkweighing ensures that each product meets the required weight specifications and complies with regulatory standards.

The dynamic checkweighers featured at the exhibition impressed attendees with their ability to weigh food products at high speeds without slowing down the production line. With throughput capabilities of up to hundreds of units per minute, these machines are ideal for high-volume production environments where speed, accuracy, and efficiency are paramount.

What makes these checkweighers stand out is their integration with data traceability software, which allows manufacturers to track weights and ensure compliance in real time. If a product is outside the acceptable weight range, the system can automatically reject it, reducing the risk of overfill or underfill issues. This automation also eliminates the need for manual checks, saving both time and labor costs.

Metal Detectors: Enhancing Quality Assurance

When it comes to metal detection, Easyweigh and Foodman’s metal detectors were also on display. These machines are designed to detect metal contaminants in food products, which can range from small metal fragments to larger pieces of ferrous, non-ferrous, and stainless steel materials. Metal contamination can be a significant risk in food production, especially in industries like meat processing, where metal parts from machinery can accidentally make their way into the product.

The metal detectors featured in the exhibition were capable of detecting a wide range of metal contaminants at extremely high sensitivities. Advanced features, such as automatic rejection systems, were incorporated to prevent any contaminated products from continuing along the production line.

Whether it’s meat or poultry, manufacturers can rely on these FDA-approved and HACCP-compliant metal detectors to ensure that their food products are safe for consumption. At the event, attendees were able to see how these machines worked in real-time, enhancing their understanding of how metal detection and quality assurance work hand-in-hand.

Global Networking and Insights at GULFOOD MANUFACTURING

In addition to showcasing cutting-edge technology, Easyweigh and Foodman also benefited from the networking opportunities at GULFOOD MANUFACTURING. The exhibition was a melting pot of ideas and innovation, drawing industry leaders, suppliers, and manufacturers from all over the world. Easyweigh’s presence at the event helped foster deeper connections with current partners and opened doors for new collaborations and business opportunities.

With a global presence in markets like Europe, Asia, and North America, Easyweigh and Foodman were able to discuss the latest trends in automated sorting, food safety, and quality control technologies with experts and professionals from all over the world. Insights gained from these interactions will be invaluable as they continue to evolve and expand their product offerings to meet the ever-growing needs of the food manufacturing industry.

Looking Ahead: The Future of Food Manufacturing

The success of Easyweigh and Foodman’s participation in the GULFOOD MANUFACTURING 2025 exhibition marks another milestone in their journey to provide high-quality, reliable, and innovative food processing solutions. From advanced sorting machines to X-ray inspection systems and checkweighers, the company is leading the way in food safety, quality assurance, and production efficiency.

As the food manufacturing industry continues to evolve, Easyweigh and Foodman are committed to staying at the forefront of technological advancements. The feedback and connections made at GULFOOD MANUFACTURING 2025 will guide them in developing even more sophisticated systems to meet the needs of the global food industry.

Conclusion

The GULFOOD MANUFACTURING exhibition was a powerful reminder of how technological innovation is shaping the future of food production. Easyweigh and Foodman’s showcase of their sorting machines, X-ray inspection machines, checkweighers, and metal detectors highlighted their ongoing commitment to food safety, quality control, and operational efficiency.

For those in the food manufacturing industry, the future is brighter with these advanced technologies, making production lines faster, safer, and more reliable. And as the world continues to demand higher standards for food quality and safety, companies like Easyweigh and Foodman are ready to lead the way.