Introduction

In 2025, fruit producers rely more on smart technology. One of the most important innovations is the fruit sorting machine. This machine helps improve product quality. It reduces waste and speeds up sorting. If you work in farming, packaging, or food processing, this guide is for you.

A fruit sorting machine uses cameras and sensors. It detects size, color, weight, and defects. The machine sorts each fruit based on quality settings. Vision sorting machines are accurate and fast. These automated vision inspection systems are now common across the fruit industry.

This guide explains how machine sorting works. It highlights key features of modern vision inspection systems. You’ll also learn how tomato sorting machines, apple grading, and camera vision inspection systems improve sorting.

What Is a Fruit Sorting Machine?

A fruit sorting machine is an industrial machine that automates the sorting and grading of fruits. It replaces slow and inconsistent manual labor with fast image processing and smart sensors. The machine checks each fruit to ensure quality and meet buyer standards.

Most modern sorting machines check for:

Size: Small, medium, or large based on diameter or volume.

Color: Ripeness, even skin color, or surface discoloration.

Weight: Accurate grouping for packing and sales.

Shape: Removal of misshaped or damaged fruit.

Defects: Spots, bruises, mold, or insect damage.

Each fruit goes through a machine vision inspection system. This system takes sharp images from many angles. The system then analyzes each image using software that mimics human vision. Fruits are sorted using air jets, or pushers.

Fruit sorting machines come in different types. Some are best for soft fruits like strawberries. Others handle firm fruits like apples or pears. Whether you’re preparing fruits for the supermarket or for juice production, a fruit sorter can improve output and consistency. It ensures your products meet both visual and internal quality standards.

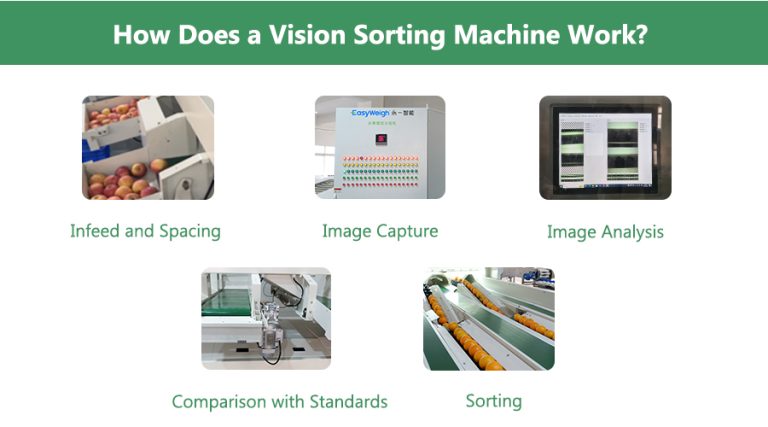

A vision sorting machine works by following a step-by-step process. It uses cameras, sensors, and software to examine each fruit and decide how to sort it.

Infeed and Spacing: Fruits are placed on a moving belt and spaced evenly.

Image Capture: High-speed cameras take detailed images as the fruit moves through.

Image Analysis: The vision system for quality inspection studies shape, size, color, and defects.

Comparison with Standards: The system checks if the fruit matches pre-set grades.

Sorting: Fruits are moved to different bins based on the result.

Modern vision systems for inspection also use AI. They learn from past data and improve over time. These systems can detect small flaws like cracks, burns, or bug bites. Some machines even use infrared or hyperspectral sensors to see inside the fruit.

These automated vision inspection systems are easy to adjust. Operators can set different sorting rules for each type of fruit. The system is user-friendly, so even new workers can manage it. This makes vision sorting machines useful for exporters, farmers, and large food factories.

Types of Fruit Sorting Machines

There are several types of fruit sorting machines. Each one works best for certain fruits or needs. Choosing the right one depends on your product and quality goals.

1. Color and Size Sorters

These sorters check how fruits look. They group them by brightness, hue, and size. They are often used for apples, oranges, and mangoes. This helps make fruit trays look clean and uniform.

2. Weight-Based Sorters

These sorter machines use weight to group fruits. They are popular in packing lines. They make sure each box or bag has the correct weight.

3. Defect Detection Systems

These vision sorter systems spot problems on the fruit surface. They find rot, cuts, and marks using a vision inspection system. This is important for top-grade products.

This vision sorter machine focuses on tomatoes. It removes ones that are too ripe, too green, or damaged. It’s a must-have for tomato product factories.

5. Apple Grading Machine

This machine helps in apple grading. It checks for color, size, and shape. It makes sure apples in the same box look alike.

Each of these machines uses a camera vision inspection system. Some models inspect two or three lines at the same time. This saves time and boosts sorting speed.

Automated vision inspection systems help fruit businesses in many ways. These are the top benefits:

Accuracy: They find small flaws that workers might miss. This leads to fewer complaints and better brand value.

Speed: These machines can sort thousands of fruits every hour. This helps meet large orders on time.

Fewer Workers Needed: Fewer people are needed to check each fruit. This saves money.

Consistency: The same sorting rules apply to every fruit. This ensures quality remains stable.

Live Monitoring: The system gives data reports. Managers can watch performance and fix problems early.

Using a vision inspection system improves quality, reduces mistakes, and builds customer trust. These systems are now a key part of modern food production.

Machine Sorting in the Fruit Industry

Machine sorting has changed the way fruit is handled. Manual sorting is too slow and often wrong. Fruit sorting machines give fast, repeatable, and traceable results.

Inspect vision systems are the engine behind this change. They check every fruit using rules set by the user. These machines are used in:

Farms that grow many fruit types

Export companies

Juice and puree factories

Storage and shipping centers

The machines can process large batches and keep quality high. They also record useful data. This includes how many fruits were rejected and why. Even small farms are now using vision sorting machines. Lower costs and easier systems have made this possible. Machine vision inspection systems are also easy to care for and don’t break down often.

Operator Training and System Integration

Training is important if you want to get the best out of a fruit sorter. Many companies offer operator training online to make this simple.

Training includes:

How to turn the machine on and off safely

How to change sorting settings

How to clean and fix small problems

Good training helps your team avoid errors. It also keeps the machine running smoothly. A trained worker can adjust the vision inspection system to match different fruits or seasons.

System integration is also key. Your vision sorting machine should connect with other parts of the line—like conveyors and packing stations. When systems work together, everything moves faster.

Connected systems let managers check performance remotely. They can plan shifts better and avoid downtime. This boosts output and saves time.

Conclusion

In 2025, a fruit sorting machine is a smart investment. It helps you deliver better products, save money, and meet demand.

Whether you sort apples, berries, or tomatoes, a vision sorting machine gives you speed and accuracy. Backed by strong machine sorting and modern automated vision inspection systems, it’s the future of food processing.

Train your team with operator training online. Link your machines for better workflow. Choose a powerful fruit sorter. And lead your market with confidence, quality, and performance.

FAQs

What does a fruit sorting machine do?

A fruit sorting machine is an machine that automatically sorts fruit by size and weight. It considers factors like size, color, weight, shape and any defects. It quickly and accurately separates fruit by means of vision inspection systems and sensors. That results in faster processing, less waste, and reduced labor costs.

Do fruit sorting machines sort volumes for defects into fruit?

Yes, they can! These fruit sorter machines are geared to spot surface defects, such as bruises, cuts or mold. More advanced systems can go a step further, employing infrared or hyperspectral imaging to detect internal problems. So if there’s something wrong with the fruit, it won’t make it past the sorter.

How to select the right fruit sorting machine?

When choosing the right machine, ask yourself a few questions:

- What sort of fruit are you grading, also what is the problem with it?

- How fast do you want this machine to be?

- Does it have to find imperfections?

- Will it work with your existing setup?

- How user-friendly is it, and how much automation do you want?

Be certain you choose a provider that has plenty of experience in regards to vision inspection systems. They should serve to steer you in the right direction.