Introduction

Cheese and dairy products play a vital role in global nutrition. With rising consumer demand and stricter food safety standards, ensuring the safety and quality of dairy products is more critical than ever. Contaminants in dairy products can harm consumers and damage brand reputation.

To combat this, advanced technologies like x ray inspection systems and food metal detectors are essential. These solutions provide smart, real-time inspection to detect physical contaminants like metal, glass, and bone. Whether you’re producing cheese blocks or milk powder, implementing smart inspection systems can safeguard product integrity and meet global safety standards.

In this blog, we explore how x ray food inspection and food metal detection improve cheese and dairy product safety. We’ll also discuss how these technologies work, which contaminants they detect, and why they are crucial for the modern dairy industry.

The Challenges of Dairy Product Inspection

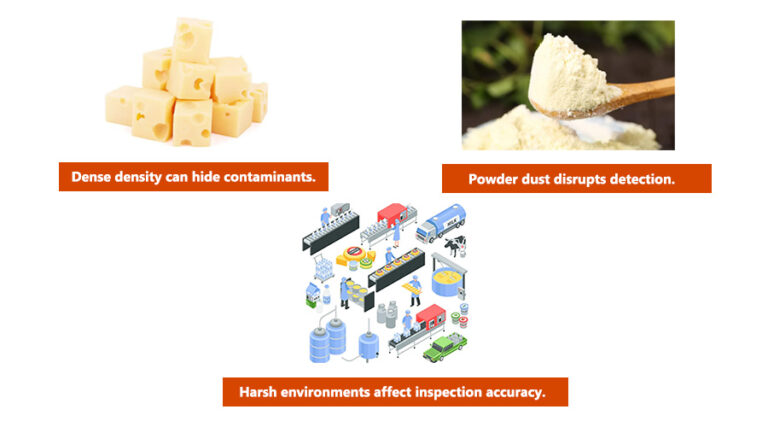

Dairy products come in many forms: milk, cheese, yogurt, butter, cream, and powdered products. Each has unique challenges when it comes to inspection.

For example, soft cheese may conceal contaminants due to its density. Meanwhile, milk powders can generate dust and require enclosed inspection systems. Dairy factories also face fluctuating temperatures, high moisture, and fast conveyor speeds.

These challenges demand specialized equipment:

- X ray inspection machines for dense products like cheese blocks

- Conveyor metal detectors for high-speed dairy production lines

- Non ferrous metal detectors to identify stainless steel and aluminum fragments

- Pipe x ray systems for liquid milk and yogurt inspection

Without proper inspection, foreign bodies like broken blades, wire, or metal fragments can enter the product line. These detected metal contaminants pose serious safety hazards.

The Role of X Ray Inspection Systems in Dairy Safety

What is an X Ray Inspection System?

An x ray inspection system uses dual-energy X-rays to scan the inside of food products. It detects physical contaminants such as metal, glass, stone, rubber, and even bones.

In dairy production, x ray inspection systems are particularly effective. They can scan large blocks of cheese, trays of yogurt, or powdered milk bags. Their sensitivity remains high, even with varying product densities.

Detects more than metal detector: Unlike metal detectors, x ray food inspection also identifies non-metallic contaminants like glass and bone.

No product effect: Salt or moisture levels in cheese don’t affect performance.

High accuracy: Identifies small fragments, even in dense or overlapping products.

A water cooled x ray system is ideal for dairy plants, where machines operate continuously. Cooling helps prevent overheating during extended shifts.

Applications in Dairy Facilities

- Cheese blocks: Check for fragments from cutting blades.

- Yogurt packs: Inspect for glass shards from packaging.

- Milk powder bags: Scan for aluminum and other foreign particles.

- Liquid dairy: Use pipe x ray systems in enclosed pipelines.

By using a food x ray machine, you ensure dairy products are clean, safe, and compliant with global food safety regulations.

Metal Detection for Dairy Products

What is a Food Metal Detector?

A food metal detector uses electromagnetic fields to identify metal fragments in food products. These can be ferrous (iron), non ferrous metals (like copper or brass), or stainless steel.

Conveyor metal detectors are widely used in dairy processing lines, especially where products are packaged and sealed. They are designed to inspect a continuous flow of products on a belt.

Why Metal Detection is Critical for Dairy

Metal fragments can originate from:

Machinery parts

Processing tools

Packaging equipment

Maintenance activities

Even a small detected metal particle can cause injury or damage a customer’s teeth. This leads to complaints, recalls, or lawsuits.

Can Metal Detectors Find Aluminum?

Many dairy packages, like foil-wrapped cheese or aluminum-lid yogurt cups, raise an important question: Can metal detectors find aluminum?

Yes, but only if you’re using the right detector. A non ferrous metal detector for aluminum foil packaged is capable of detecting aluminum packaged products. Advanced metal detectors offer multi-frequency scanning for higher accuracy in complex dairy environments.

When to Use a Food Metal Detector

- Low-density products like milk sachets or yogurt tubs

- Final product inspection on conveyor metal detector systems

- Cost-effective solution for facilities with lower contamination risk

Food metal detectors are budget-friendly and effective for most dairy inspection needs.

When to Use an X Ray Inspection Machine

Dense products like cheese wheels or blocks

Detection of non-metallic contaminants

Compliance with export regulations requiring full-body inspection

A food x ray inspection machine provides deeper inspection and higher accuracy. For full product traceability, a food x ray machine with imaging storage is preferred.

Some manufacturers choose to integrate both solutions—placing a metal detector at the packaging line and an x ray inspection system earlier in the process. This layered approach ensures no contaminant is missed.

Advanced Dairy Inspection with Easyweigh Solutions

Water Cooled X-Ray System for Dairy Plants

Easyweigh’s water cooled xray system is built for continuous operation in high-temperature environments. Foodman Food X-Ray Inspection System for Packaged Product is ideal for cheese factories or milk powder lines that run 24/7.

- Efficient heat dissipation

- Longer equipment lifespan

- Consistent detection accuracy

Pipe X Ray Inspection for Liquid Dairy

For products like milk, cream, and yogurt, Easyweigh offers advanced pipe x ray solutions. Foodman Pipeline X-Ray Inspection System inspects liquids during flow, before they are filled into containers.

- Hygienic stainless-steel pipes

- CIP (Clean-in-Place) design

- Accurate real-time scanning

This ensures safety before the packaging stage—reducing risk and minimizing waste.

Dual Energy Food X Ray Equipment for Dairy Blocks

Large cheese blocks and butter slabs require powerful food x ray equipment to penetrate dense layers. Foodman’s dual energy x ray food inspection equipment is tuned for these applications.

- Dual-energy imaging available

- Detects dense and soft contaminants

- Image recognition and sorting capabilities

Whether it’s a soft ricotta cheese or hard cheddar block, the x ray food inspection system provides clear internal visualization.

Conveyor Metal Detector For Aluminum Foil Packaged Products for Dairy Lines

Packaged Products for Dairy Lines

Our conveyor metal detector systems are designed to handle even aluminum foil packaged dairy:

- Packaged cheese

- Cartons of yogurt

- Bags of milk powder

Aluminum Foil Metal Detector are IP66-rated, ideal for wash-down environments. With non ferrous metal detection and multi-frequency technology, they detect both small and large contaminants reliably.

Compliance, Traceability, and Global Standards

Food safety regulations are tightening worldwide. The dairy industry must comply with standards such as:

HACCP (Hazard Analysis and Critical Control Points)

FDA (U.S. Food and Drug Administration)

BRCGS (British Retail Consortium Global Standard)

Smart inspection solutions like x ray inspection systems and food metal detectors play a key role in meeting these standards.

They also support digital traceability. Most modern systems log inspection results, record detected metal, and integrate with ERP systems. This helps with:

Auditing

Product recalls

Quality assurance reports

Using a food x ray inspection machine is not just about safety—it’s about brand protection and regulatory compliance.

Conclusion

Cheese and dairy manufacturers face increasing pressure to deliver high-quality, contaminant-free products. With the complexity of dairy processes, smart inspection is no longer optional—it’s essential.

By investing in a reliable x ray inspection system or food metal detector, you protect your brand, ensure consumer trust, and stay ahead of global food safety regulations.

Whether you need a conveyor metal detector, a non ferrous metal detector, or a pipe x ray system, Easyweigh and Foodman offers solutions tailored for every stage of dairy production. Our x ray food machines, food x ray equipment, and water cooled xray systems are designed to meet the unique challenges of dairy inspection.

Explore the future of dairy safety with Easyweigh and Foodman. Your peace of mind—and your customer’s safety—depend on it.

FAQs

A: An dual energy x ray inspection system can detect metal, glass, stone, rubber, plastic, and bone fragments in dairy products. It is especially effective for dense items like cheese blocks and powdered milk. These latest systems go beyond what traditional food metal detectors can detect.

A: Absolutely—if they use non ferrous metal detectors For Aluminum Foil Packaged Products. These are capable of detecting aluminum foil packaged dairy.

A: A food metal detector detects ferrous and non ferrous metal contamination, while an x ray inspection machine can detect both metal and non-metal contaminants like glass or stone. For high-risk dairy items like cheese wheels or glass-packaged yogurt, x ray food inspection is more comprehensive.