Introduction

In 2025, food safety remains a top priority for global food manufacturers. Whether producing sauces, slurries, yogurt, or minced meats, manufacturers need advanced inspection tools that work seamlessly inside pipelines. This is where a pipeline X-ray inspection system becomes essential.

Unlike belt inspection systems, pipeline X-ray equipment is designed specifically for liquids, semi-liquids, and pastes. It detects contaminants that are invisible to the human eye and even some traditional machines. These include metal fragments, bones, glass shards, rubber, and certain plastics.

In this guide, we explore everything you need to know about a pipeline X-ray, from how it works to its components and applications. We’ll also answer common questions like does plastic show up on X-ray?, can you see glass on X-ray?, and what are the components of an X-ray machine? If you’re searching for a trusted X-ray machine supplier or considering investment in industrial X-ray machines, this article is for you.

What Is a Pipeline X-Ray Inspection System?

A pipeline X-ray inspection system is an advanced form of industrial X-ray machine used to inspect viscous or fluid products while they move through pipes during processing. Unlike traditional food X-ray equipment, which scans products on a belt, pipe X-ray systems scan the liquids and semi-liquid products directly internally within a closed system.

These machines are designed to detect foreign bodies like metal, glass, bone, rubber, and even some plastics. This means they answer the common question: does plastic show up on X-ray? In many cases, yes—especially if the plastic differs in density from the surrounding product.

How Pipeline X-Ray Equipment Works

Pipeline X-ray equipment functions by using precision X-ray technology. The liquids and semi-liquids product (such as sauce or jam) flows through a sanitary pipe, and the X-ray pipeline inspection system sends X-rays through the material. A detector captures the image and compares it to a known safe standard of a product. Sophisticated software analyzes the image in real time, identifying foreign objects.

If a foreign object is detected—such as glass on X-ray or metal—the system activates an automatic reject valve. This removes the contaminated portion before it reaches the packaging line, ensuring food safety without interrupting production.

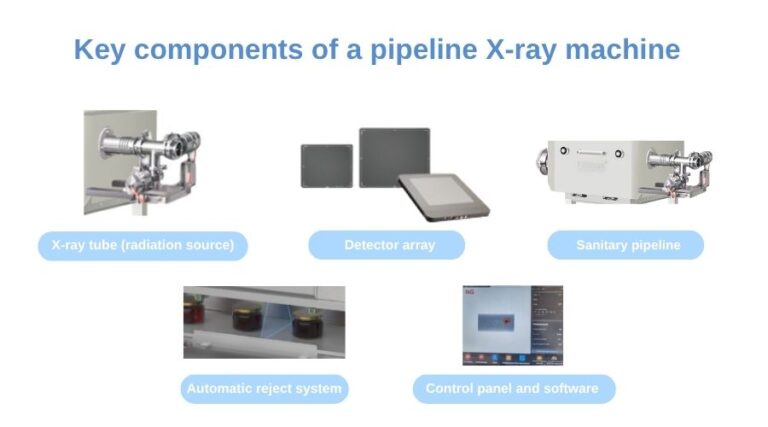

Key components of a pipeline X-ray machine include:

- X-ray tube (radiation source)

- Detector array

- Sanitary pipeline

- Automatic reject system

- Control panel and software

These are part of the essential components of X-ray machines used in the food industry. The combination of these parts creates a highly sensitive, real-time inspection system tailored for pumped products.

What Contaminants Can a Pipeline X-Ray Detect?

One of the most frequent questions is: can you see glass on X-ray? The answer is yes. Most pipeline systems can detect glass, especially dense fragments. That means your system can answer: does glass show up on an X-ray? again, yes—with high-resolution detectors and proper calibration. Detection sensitivity depends on the material density contrast and system configuration.

- Other detectable contaminants include:

- Metal fragments (ferrous, non-ferrous, stainless steel)

- Bone fragments (ideal for chicken X-ray inspection)

- Glass shards (from broken jars or equipment)

- Rubber gaskets or plastic pieces

- Stones and dense soil particles

That also answers: does plastic show up on X-ray? If the plastic is dense or hard, the answer is often yes. Detection is also possible for items embedded in thick or opaque products, provided the imaging contrast is sufficient.

Why Choose a Pipeline X-Ray Over Metal Detectors?

While metal detectors are useful, they only find metal. A pipeline X-ray inspection system goes further. It finds glass on X-ray, bone, rubber, and even some types of plastic. This means fewer recalls and safer products. With growing scrutiny from food safety authorities, this comprehensive detection gives manufacturers a critical advantage.

In addition, metal detectors can be affected by product moisture or salt content. Precision X-ray systems are not. That makes X-ray pipeline inspection more stable and accurate for wet, dense products. It’s a more dependable option when consistency and quality are non-negotiable.

If your product is pumped through pipes—like dairy, sauces, or ground meat—you need a reliable food X-ray equipment solution. A pipeline X-ray machine is the best choice. It integrates directly into your pipeline with minimal disruption, maximizing uptime and efficiency.

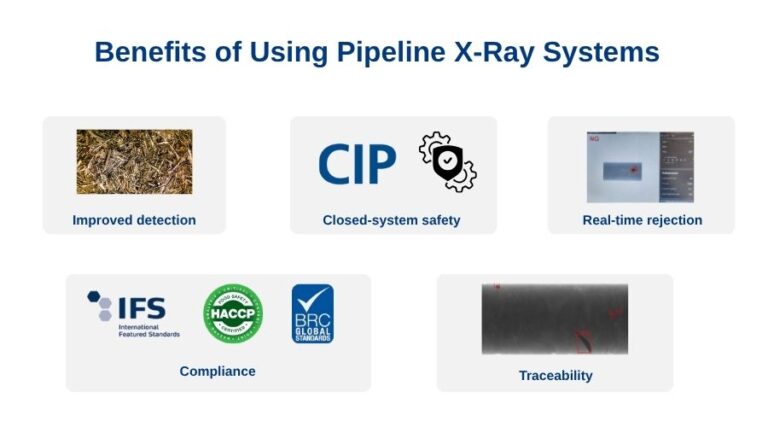

Investing in a pipeline X-ray inspection system provides many advantages:

- Improved detection: Finds what metal detectors can’t, including non-metallic materials.

- Closed-system safety: Ideal for hygienic food handling and clean-in-place (CIP) setups.

- Real-time rejection: Contaminants removed immediately without halting production.

- Compliance: Meets international food safety standards such as HACCP, BRC, and IFS.

- Traceability: Image records and batch tracking for full audit readiness.

- The pipeline x-ray machine can be directly connected to the front conveying device, such as Vemag filling machine, etc.

If you’re evaluating industrial X-ray machines, consider the ROI. Reduced recalls, improved brand reputation, and minimized product loss translate to substantial long-term savings.

Who Needs a Pipeline X-Ray Machine?

Pipeline X-ray machines are essential in industries where products are fluid or semi-fluid. These include:

- Dairy (yogurt, cream, milk-based drinks)

- Meat processing (especially chicken X-ray for bone detection)

- Sauces and dressings

- Baby food and purees

- Soup and paste products

These products typically require enclosed systems due to hygiene concerns and are prone to hidden contamination. If you’re a X-ray machine supplier or work in equipment procurement, adding pipeline X-ray equipment to your offering will attract clients in these industries and improve your product portfolio.

Training and Operation

Operating a pipeline X-ray inspection system requires basic knowledge. Fodman, which x ray machine supplier offer basic X-ray machine operator training online. This ensures safety, compliance, and proper maintenance. It also reduces errors and downtime.

Operators learn how to calibrate the precision X-ray, test for false positives, and maintain pipeline X-ray equipment to industry standards. Training often includes procedures for daily checks, performance validation, and reporting. This empowers quality assurance teams to fully utilize the system’s capabilities.

How to Choose the Right X-Ray Machine Supplier

Selecting the right X-ray machine supplier is critical. Look for a company that offers:

- Proven industry experience and customer success stories. Easyweigh has 16 years of experience in X-ray machines

- Certified industrial X-ray machine models with global compliance

- Ongoing support and maintenance services

- Operator training options (including basic X-ray machine operator training online)

- Integration with existing production lines and software platforms

The right supplier will help you meet both food safety standards and production efficiency goals. Partnering with an experienced vendor ensures smooth deployment, training, and long-term operational support.

Conclusion

In 2025, investing in a pipeline X-ray inspection system is a strategic move for food manufacturers. These industrial X-ray machines offer high-precision inspection for liquids, slurries, and pastes. They detect metal, bone, glass on X-ray, and even some plastic contaminants that metal detectors miss.

If you’ve ever asked, can you see glass on X-ray?, does plastic show up on X-ray?, or what are the components of X-ray machine systems?—this technology provides the answer.

With growing demand for safety, working with a trusted X-ray machine supplier and investing in advanced pipeline X-ray equipment will give your operation a competitive edge.

Choose wisely. Choose precision. Choose the future of food safety.

FAQs

Can glass be seen on an X-ray?

Yes. Glass can be detected by most pipeline X-ray systems. Dense glass fragments are visible when the system is properly calibrated.

What is a pipeline X-ray inspection system?

A x ray pipeline inspection is a machine used to check liquid and paste products inside a pipe. It detects foreign objects like metal, glass, and bone in liquid productsduring production.

How do I choose the right X-ray machine supplier?

Look for a supplier with food industry experience. Easyweigh offer certified machines, training, service support, and good customer reviews.