How Does X-Ray Inspection Work?

1.1 The principles of X-ray Inspection Technology

X-ray Inspection Technology uses powerful X-rays to see inside objects, such as food, by passing through them. X-ray machines use X-ray generators to emit beams that interact differently with materials depending on their density and composition.

The system uses X-rays to find differences in density and locate foreign objects in food. X-ray inspection is important for food safety and quality in the food industry. It includes systems and machines for inspecting food using X-rays.

1.2 How does X-ray inspection technology detect foreign objects in food products?

X-ray technology finds foreign objects in food using X-ray beams that go through the product. As the X-rays interact with the materials, their absorption levels vary depending on the density and composition.

Metal or bone absorbs X-rays more and shows up as dark areas in X-ray images. Less dense materials, such as plastic or organic matter, absorb fewer X-rays and appear as lighter areas.

X-ray inspection systems and food X-ray machines can create detailed images of the inside of a product. They do this by studying absorption changes. Trained operators or automated algorithms examine these images to identify and flag foreign objects, including glass or plastic contaminants.

1.3 Can x-ray inspection detect non-metallic contaminants such as glass or plastic?

X-ray inspection technology can detect non-metallic contaminants such as glass or plastic in food products. Metal detectors find metal contaminants, while X-ray systems detect various foreign objects, regardless of their material.

X-rays can tell the difference between different substances by their interaction with materials based on density and atomic number. Non-metallic contaminants, such as glass or plastic, have densities that differ from the surrounding food. As a result, they appear distinct when X-rayed.

This allows X-ray machines to show differences in the X-ray image, including those in food X-ray machines. Trained people or computer programs can check the picture to find and mark things that are not metal. This makes sure that food is safe and good quality.

How Does Metal Detection Work?

2.1 Principles of Metal Detection Technology

Metal Detection Technology uses electromagnetic fields to find metal contaminants in substances like food.

Metal detectors operate on a balanced, three-coil system that detects non-ferrous and stainless steel particles. When a metal object passes through the coils, it disrupts the high-frequency field, resulting in a change in voltage.

The metal detector then analyzes this change, triggering an alert or rejection mechanism. Metal detection technology, such as metal detectors and food metal detectors, ensures the safety and quality of food. It accomplishes this by detecting and removing any metal impurities present.

2.2 Can metal detection systems detect different types of metals?

Metal detection systems detect different types of metals. They can find various types of metals. Some of these metals contain iron, while others do not.

Examples of metals without iron include aluminum, copper, and lead. Another type of metal they can find is stainless steel.

You can adjust the sensitivity settings of metal detectors to detect specific metals based on their conductivity and magnetic properties.

By utilizing different frequencies and sensitivity levels, metal detection systems can effectively identify and distinguish between various types of metals. This capability allows them to ensure comprehensive metal detection and removal in food production processes, maintaining the highest food safety standards.

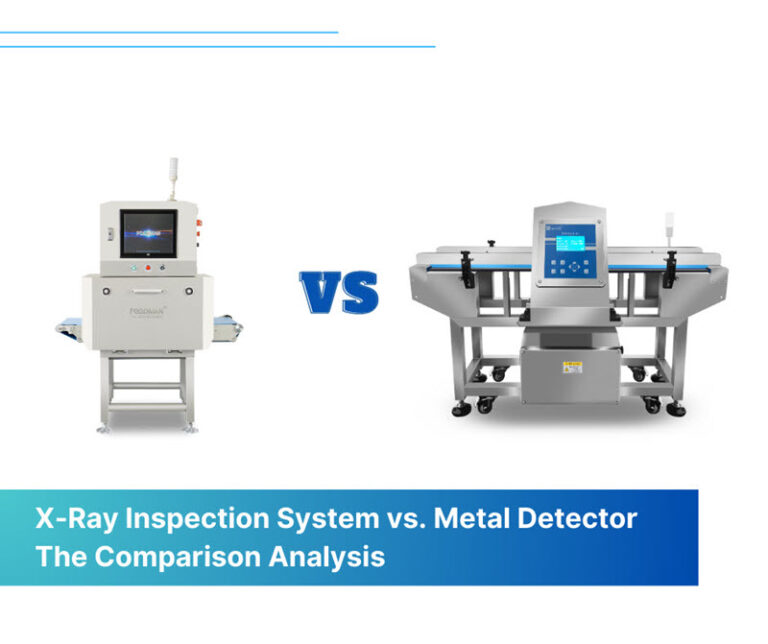

Comparative Analysis: X-Ray Inspection vs. Metal Detection

Here’s an Excel list showcasing the differences between X-ray inspection and metal detection in terms of detecting foreign contaminants in food products:

| X-ray Inspection System | Metal Detection | |

|---|---|---|

| Detection Method | Uses high-energy electromagnetic radiation | Relies on disturbances in a magnetic field |

| Scope of Detection | Detects metallic and non-metallic contaminants | Primarily detects metallic contaminants |

| Sensitivity and Accuracy | High sensitivity and accuracy | High sensitive compared to X-ray inspection in detecting metallic contaminants |

| Packaging Compatibility | Can penetrate various packaging materials | Works effectively through non-metallic packaging |

| Versatility | Suitable for a wide range of contaminants and products | Primarily focused on metallic contaminants |

| Image Visualization | Generates detailed images of the product's interior | Typically does not provide visual images of contaminants |

Suitability and Applications

3.1 Can X-ray inspection systems detect contaminants through aluminum foil packaging?

X-ray inspection systems can detect contaminants through aluminum foil packaging. Aluminum foil is generally transparent to X-rays, allowing the inspection system to penetrate the packaging and analyze the contents.

X-rays detect foreign objects, including metal, glass, stone, bone, and certain plastics. The system can distinguish between the product and other objects based on density and composition.

X-ray inspection systems can still function even if the product is in aluminum foil. X-ray inspection is an effective solution for ensuring product safety and quality in food products with aluminum foil.

3.2 Can metal detectors detect contaminants in products with metallic or reflective packaging?

Metal detectors can detect metallic contaminants in food products. They can effectively identify and alert the presence of ferrous and non-ferrous metals such as iron, steel, aluminum and copper.

However, metal detectors may face challenges when inspecting metallic or reflective packaging products. The metal detector’s sensitivity may decrease due to the presence of packaging material, resulting in reduced detection capabilities.

The metal detector settings can be adjusted to reduce interference from packaging material and improve detection sensitivity.

For metallic or reflective packaged products, use X-ray inspection to detect contaminants effectively.

Making the Right Choice: Factors to Consider

4.1 What factors should I consider when deciding between a metal detector and an X-ray inspection system?

When deciding between a metal detector and an X-ray inspection system, it’s important to take several factors into account.

Firstly, consider the type of contaminants you need to detect. Metal detectors detect only metal, while X-ray systems detect a wider range of substances including non-metallic materials.

Secondly, consider the nature of your products and their packaging. Metal detectors for specific items, and X-ray systems for greater flexibility.

Finally, cost, maintenance requirements, compliance with regulations, and the level of expertise needed for operation are essential considerations.

4.2 How does the sensitivity and accuracy of a metal detector compare to an X-ray inspection system?

Regarding sensitivity and accuracy, X-ray inspection systems have an advantage over metal detectors. Metal detectors can detect larger metal contaminants, but they may have limitations in detecting smaller or non-metallic contaminants.

X-ray systems detect contaminants of all sizes and materials, including metal, glass, stone, and plastic. They analyze density differences and generate detailed images, ensuring precise detection and reducing the chances of false positives or negatives.

X-ray inspection systems are preferred over metal detectors for food impurity detection due to their precision and high sensitivity.

Conclusion

In summary, the choice between X-ray inspection systems and metal detectors depends on various factors. Manufacturers should consider foreign contaminants, product characteristics, packaging, cost, maintenance requirements, regulatory compliance, and expertise.

X-ray inspection technology offers superior sensitivity and versatility, detecting both metallic and non-metallic contaminants, including through aluminum foil packaging. Metal detectors excel in detecting metallic contaminants.

Consider your specific requirements to make an informed decision for ensuring the safety and quality of food products. Opt for the technology that best suits your needs and invest in a reliable solution for effective contaminant detection.