Introduction: Food Safety Is Everyone's Business

Consider this: you are at your favorite seafood joint, having grilled salmon ordered for you. You expect the fish to be fresh, boneless, and safe to consume. But behind the scenes, dozens of things can go wrong—bacteria on the fish, cross-contamination in the kitchen, or even microscopic fragments of plastic from packaging.

This is where HACCP steps in. If you’ve ever wondered what is HACCP, what does HACCP mean, or even HACCP what does it stand for, you’re not alone. Many people in the food industry hear the term but don’t fully understand why it’s such a big deal.

The truth of the matter is that hazard analysis critical control point HACCP food safety is the foundation of food safety systems today. It’s not a case of box ticking for the authorities. It’s about protecting consumers, keeping companies trading, and building and maintaining trust within an industry where one misstep can send reputations crashing overnight.

In this article, we’ll explore what is HACCP definition, explain what is a HACCP plan, break down HACCP control points, and show why every food business needs a HACCP plan.

What Is HACCP?

So, let’s start simple. What is HACCP mean?

HACCP stands for Hazard Analysis and Critical Control Points. At its core, it’s a preventive system. Instead of waiting to test finished products, HACCP looks at the production process step by step to spot risks before they happen.

When someone asks, what’s HACCP or what is a HACCP, the answer is straightforward:

HACCP is an internationally recognized food safety system that helps businesses identify hazards, set controls, and keep food safe.

It’s not just for big factories either. From small bakeries to seafood exporters, everyone benefits from applying hazard analysis critical control point HACCP.

What Does HACCP Stand For?

One of the most common questions is: HACCP what does it stand for?

The acronym breaks down into:

H – Hazard

A – Analysis

C – Critical

C – Control

P – Points

In other words, HACCP is about analyzing hazards and setting up HACCP control points to keep food safe.

Why HACCP Matters More Than Ever

Let’s be honest—food safety scandals make headlines all the time. Think about metal foreign objects in chicken. For consumers, these are scary. For businesses, they’re catastrophic.

So, what is HACCP in food industry terms? It’s the line of defense that protects everyone. HACCP safety food systems save businesses from costly recalls, protect consumers from harm, and keep regulators satisfied.

Imagine if your bakery sold bread contaminated with metal shavings. Without a system like HACCP, you might never catch the problem until customers complain. By then, your reputation could be gone.

Here’s the big one: what is a HACCP plan or what is HACCP plan exactly?

Think of a HACCP plan as the blueprint for food safety in your business. It’s not just paperwork—it’s the practical guide your team follows every day.

It includes:

The hazards you’ve identified.

The HACCP points where those hazards can be controlled.

The HACCP critical limits that define what’s safe.

The monitoring systems HACCP relies on (like temperature logs or visual checks).

Corrective actions for when things go wrong.

Verification and record-keeping steps to prove compliance.

If you’ve ever used a recipe card while cooking, you know how it guides every step. A HACCP plan works the same way—only instead of guiding a meal, it guides the safety of your entire operation.

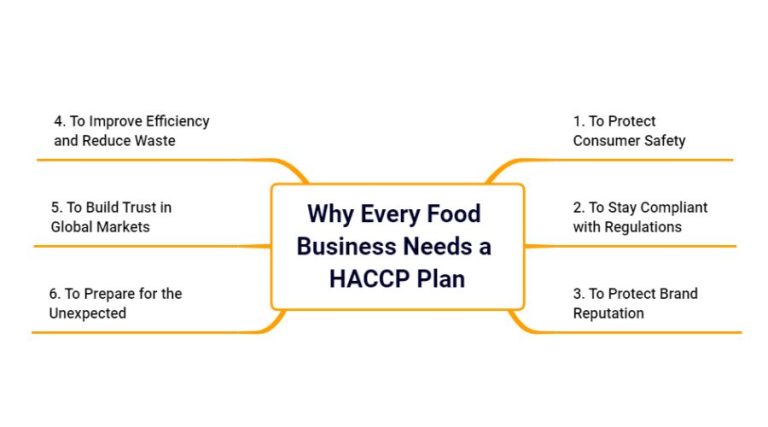

Why Every Food Business Needs a HACCP Plan

1. To Protect Consumer Safety

At the core, food businesses exist to serve safe food. Whether it’s a bakery, seafood exporter, or dairy producer, customers expect that what they eat won’t harm them.

A HACCP plan ensures this by defining hazards, setting HACCP points, and applying HACCP critical limits. Without it, safety becomes guesswork.

2. To Stay Compliant with Regulations

In many countries, regulators mandate HACCP. Failing to comply can mean fines, shutdowns, or lost licenses.

So, when business owners wonder, what is HACCP in food industry terms? It’s not just best practice—it’s often the law.

3. To Protect Brand Reputation

Consider this: metal foreign objects were found in food products. Rebuilding consumer trust after such an incident is nearly impossible.

A hazard analysis critical control point HACCP food safety system minimizes this risk. It shows customers that safety isn’t just a checkbox—it’s a priority.

4. To Improve Efficiency and Reduce Waste

Many assume HACCP is only about safety. But it’s also about efficiency. By setting monitoring systems HACCP, businesses can catch issues early—before an entire batch is wasted.

For example:

If a checkweigher catches underweight packages, adjustments can be made immediately.

If refrigeration logs show a cooler warming, food can be moved before spoilage.

This saves money, time, and product.

5. To Build Trust in Global Markets

Exports are tricky. International buyers demand strict compliance with recognized systems. Since HACCP is globally recognized, having a robust HACCP plan gives businesses credibility.

If you want to sell frozen seafood abroad, a buyer will almost certainly ask for proof of hazard analysis critical control point HACCP compliance. Without it, opportunities vanish.

6. To Prepare for the Unexpected

Equipment fails. Power goes out. People make mistakes. A HACCP plan ensures there’s a clear corrective action path for every situation.

For example, if a fridge temperature rises above the HACCP critical limits, the plan dictates whether food can be re-chilled, cooked, or must be discarded. No guessing, no chaos—just structured, safe decision-making.

Breaking Down the Components of a HACCP Plan (Simplified)

To see why it’s so important, let’s quickly outline what a HACCP plan usually includes:

Hazard Identification: Biological (bacteria), chemical (pesticides), physical (metal fragments).

HACCP Points: Stages where hazards can be controlled (cooking, chilling, packaging).

Critical Limits: Exact standards for safety, like cooking chicken to 165°F.

Monitoring Systems HACCP: Logs, checkweighing, using X-ray machine to detect foreign objects and visual inspection.

Corrective Actions: What to do when limits aren’t met.

Verification: Testing and reviewing to confirm effectiveness.

Record-Keeping: Documentation for compliance and audits.

Every food business needs these pillars to keep operations running safely.

Real-World Example: Snack Processing Without HACCP

In the snack industry, applying hazard analysis critical control point HACCP food safety practices is essential to ensure products are safe and consistent.

For example, when making potato chips or packaged nuts, businesses start by asking what is HACCP and how it fits their process.

A HACCP plan identifies potential hazards such as metal fragments from machinery or contamination during seasoning. By establishing clear HACCP control points, like frying temperature and packaging integrity.

Setting HACCP critical limits to prevent microbial growth or physical hazards, manufacturers can avoid risks before products ever reach the shelf. With reliable monitoring systems HACCP, such as automated checkweighers and visual inspections.

Snack producers can document compliance and act quickly if deviations occur.

This not only answers the question of what is HACCP in food industry but also shows why HACCP safety food standards are non-negotiable in keeping snacks safe, fresh, and trusted by consumers.

The Human Side of HACCP

Here’s the part often forgotten: HACCP isn’t just about machines or paperwork. It’s about people.

The families eating dinner without fear.

The businesses safeguarding livelihoods.

The employees trained to act with confidence when things go wrong.

When you ask, what are HACCP or what does HACCP mean, remember it’s ultimately about trust. It’s the invisible safety net behind every meal.

Conclusion: HACCP as Non-Negotiable

So, why does every food business need a HACCP plan? Because without one, you’re risking consumer health, legal trouble, wasted product, and brand reputation.

By defining hazards, setting HACCP points, enforcing HACCP critical limits, and building reliable monitoring systems HACCP, businesses don’t just meet regulations—they earn trust.

Food safety isn’t optional. It’s the foundation of every successful food business.

So the next time you hear someone ask, what is HACCP plan or what is HACCP in food industry, you can answer simply:

HACCP is the reason food stays safe—and the reason food businesses stay in business.

FAQs

What is HACCP in food processing?

HACCP in food processing refers to Hazard Analysis Critical Control Points. It is a food safety system internationally recognized. It helps food companies identify risks, set up HACCP control points, and implement HACCP critical limits to prevent hazards like contamination or spoilage.

Why is a HACCP plan required in every food company?

Every food business needs a HACCP plan because it protects consumers. It also can ensure the company’s regulatory compliance and defends brand trust. By identifying hazards, controlling them, and following all steps of HACCP plan, a HACCP plan reduces risk and supports food safety at every stage.

What is a HACCP plan and how does it work?

A HACCP plan is a written document that identifies food safety hazards, sets up HACCP points, sets up critical limits, and has monitoring systems HACCP for managing risks. It also defines corrective actions and record-keeping for total compliance.