Introduction

What is food safety? It means that all practices and measures that keep food safe for consumption. Food safety impacts every stage of the food processing production line. From primary processor to deep processor, we must ensure products are safe and harmless when they arrive at consumers.

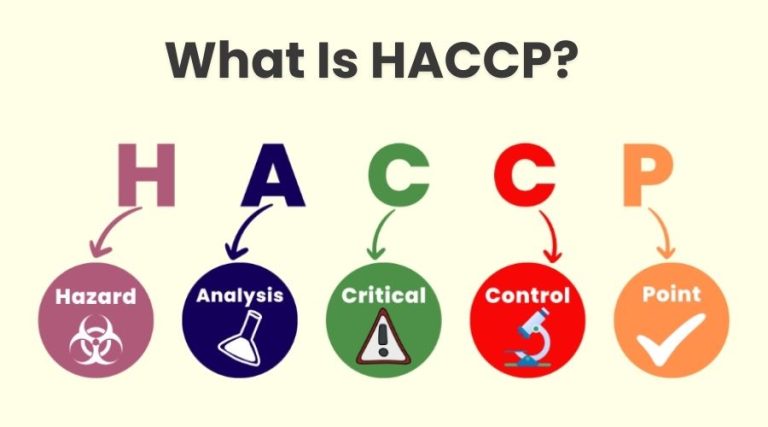

Therefore, businesses must understand how systems like Hazard Analysis and Critical Control Points (HACCP), critical control point monitoring, and food safety prevent risks. These hazards include food contamination, biological contamination, and physical contamination.

By comprehending these elements, companies can create robust food safety plans. Understand the potential hazards your food processing line may face. Know what detecting equipment to select to ensure products on the line remain uncontaminated. They also learn what is physical contamination. To comply with global food and safety regulations and maintain recognized food safety standards, companies must understand why is food safety important and adopt strategies that answer what is the best way to prevent poor food safety by addressing all types of hazard.

Understanding Food Safety

Now, let’s delve into the meaning of food safety. Food safety covers all steps to prevent food contamination and protect consumers. Whether it’s primary agricultural processing, food processing, or deep processing of pre-made meals, packaging, distribution, and even preparation at homes or restaurants. When businesses fail to prioritize safety, create comprehensive food safety plans and safe production procedures, they could potentially lead to food contamination.

For example, in 2015, contaminated ice cream in the U.S. caused multiple cases of biological contamination from Listeria monocytogenes. Without a proper food safety plan, the company paid millions in fines and lost consumer trust. This example shows why food safety is important—it protects lives, reputations, and the economy.

HACCP & Critical Control Point

What Is HACCP?

What is HACCP? HACCP stands for Hazard Analysis and Critical Control Points. It is an internationally recognized system for controlling hazards in food production. Initially developed for NASA in the 1960s, HACCP ensured astronauts’ food was safe. Today, it is mandatory in many industries under food safety regulations.

HACCP is based on seven principles:

Hazard analysis

Identifying critical control points

Establishing critical limits

Monitoring procedures

Corrective actions

Verification

Documentation

Applying HACCP helps businesses create a strong food safety plan that prevents biological contamination, physical contamination, and chemical hazards.

What Is a Critical Control Point?

A critical control point (CCP) is a step in production or handling where controls can prevent or reduce hazards. Examples include:

Heating poultry to 74°C to kill Salmonella (biological contamination)

Using metal detecting equipment to remove metal fragments (physical contamination)

Keeping cold storage at 4°C or below to prevent bacterial growth

Failing to monitor CCPs can lead to widespread food contamination. Effective CCP management ensures compliance with food safety regulations while protecting consumers.

Types of Hazard in Food Safety

Recognizing types of hazard is essential for prevention. They are grouped as follows:

Biological Contamination

Biological contamination occurs when pathogens like bacteria, viruses, or parasites enter food. Examples include:

Salmonella in undercooked eggs

E. coli in undercooked beef

Listeria in unpasteurized dairy

Dairy industry methods such as pasteurization are used to eliminate these risks.

Physical Contamination

What is physical contamination? It is when foreign objects like glass, metal, or plastic enter food. For instance, a bolt from machinery may end up in packaged soup. Modern food processing relies on metal detecting and machine vision systems to prevent such risks.

Chemical Hazards

Chemical hazards involve residues from pesticides, cleaning products, or toxins. Strong food safety regulations ensure these remain within safe limits.

Businesses often ask, what is the best way to prevent poor food safety? The answer is a layered approach:

Create a comprehensive food safety plan based on HACCP

Train employees in hygiene and safety practices

Use metal detecting and machine vision systems to catch food contamination

Conduct regular audits to comply with food and safety regulations and food safety standards

For example, a global chocolate manufacturer avoided a multimillion-dollar recall when its metal detecting system flagged a machinery fragment during packaging. Prevention is far more effective and cost-efficient than reacting to a recall.

Food Safety and Inspection

Food safety and inspection ensures consistent monitoring and control. Inspections include:

Checking metal detecting equipment for physical hazards

Using machine vision systems for packaging integrity

Microbiological detecting to prevent biological contamination

Inspection is not optional. It is often the last line of defense against food contamination.

Food Safety Regulations and Standards

Compliance with food safety regulations and food and safety regulations is mandatory worldwide. Examples include:

Food Safety Modernization Act (FSMA) in the U.S.

EU General Food Law

International standards by Codex Alimentarius

These regulations cover everything from CCP monitoring to dairy industry methods like pasteurization. Ignoring them risks fines, recalls, and export bans.

The Role of Technology in Food Safety

Metal Detecting

Metal detecting systems catch fragments as small as 0.5 mm, preventing physical contamination. They are used in bakeries, meat processing, and dairy plants.

The X-ray inspection system works by passing an X-ray beam through the food product. Sensors on the opposite side of the machine capture the X-ray that passes through, creating an image. Denser materials, such as metals, bones, or other contaminants, absorb more X-rays and appear as clear, defined shapes in the resulting image. The system’s software analyzes these images in real-time to detect any foreign objects, defects, or contaminants.

Vision Inspection System

Vision inspection system powered by AI scan thousands of products per minute. They detect mislabeling, packaging defects, and contaminants invisible to humans.

These technologies strengthen food safety plans, ensure compliance with food safety regulations, and help meet global food safety standards.

Conclusion

Food safety is important in each part during food processing. From HACCP and critical control point management to using metal detecting and machine vision systems, businesses must focus on preventing contamination. By complying with food safety regulations and implementing effective practices, companies can protect consumers, avoid costly recalls, and maintain a strong reputation.

A perfectly food safety plan is the foundation for any successful food business. By understanding what food safety is and how to implement the right measures, businesses can ensure their products are safe and of the highest quality.

FAQs

What is the role of an X-ray inspection system in food safety?

An X-ray inspection system is used to detect contaminants, defects, bone and foreign objects in food processing. It works by passing an X-ray beam through the food. Detect foreign objects by passing rays through materials of varying densities. These foreign objects are then visualized through imaging.This ensures that food products are safe and free from harmful contaminants before reaching consumers.

What types of contaminants can an X-ray inspection system detect?

An X-ray inspection system can detect several types of contaminants, including:

Metal fragments

Glass pieces

Plastic particles

Stones or dirt

Bone fragments (commonly in meat,fish and poultry products)

The X-ray system is also effective in detecting internal defects like cracks, air pockets, and voids within food products.

Are X-ray inspection systems compliant with food safety regulations?

Yes, X-ray inspection systems is comply with food safety regulations set by governing bodies like the FDA, EU, and Codex Alimentarius. These detecting machines are often part of the mandatory food safety practices in many regions, ensuring that food products are thoroughly inspected and meet the necessary safety standards before reaching consumers.