Introduction

Metal detectors and X-ray inspection systems are widely used in different industries. When you’re working in the food industry, product safety is everything. You’re dealing with perishable goods. Contaminants can’t slip through. So what’s the best way to ensure your products are clean, safe, and compliant? Two popular choices are metal detectors and X-ray inspection systems. Both have pros and cons. But one might suit your production line better than the other.

In this article, we’ll break down the key differences between a food metal detector and an X-ray food inspection system. We’ll help you decide which one makes the most sense for your business. Whether you’re trying to understand how does a metal detector work, wondering if metal detectors detect aluminum, or considering investing in an X-ray inspection system, we’ve got the answers.

What Is a Metal Detector?

A metal detector is a machine designed to detect unwanted metal contaminants in your products. It works by generating an electromagnetic field. When a metal item enters that field, it disturbs the signal. This disruption triggers a response, usually an alarm or rejection system.

How does a metal detector work? It depends on the type. The most common is a balanced coil system. It uses three coils: a transmitter and two receivers. The moment the signal is disrupted by metal — say, a piece of wire or a bolt — the machine flags it. This makes it ideal for detecting ferrous, non-ferrous, and stainless steel metals in packaged or unpackaged products.

What Is an X-Ray Inspection System?

An X-ray inspection system is a different kind of technology. It doesn’t rely on electromagnetic fields. Instead, it uses X-rays to scan products. The system looks at the density of the item. Any dense foreign object (metal, glass, stone, or bone) will show up clearly on the scan.

A food X-ray machine is highly versatile. Unlike metal detectors, X-ray food inspection can find non-metallic contaminants too. Think glass shards in jams or stone fragments in grains. It’s perfect when product safety can’t afford compromises.

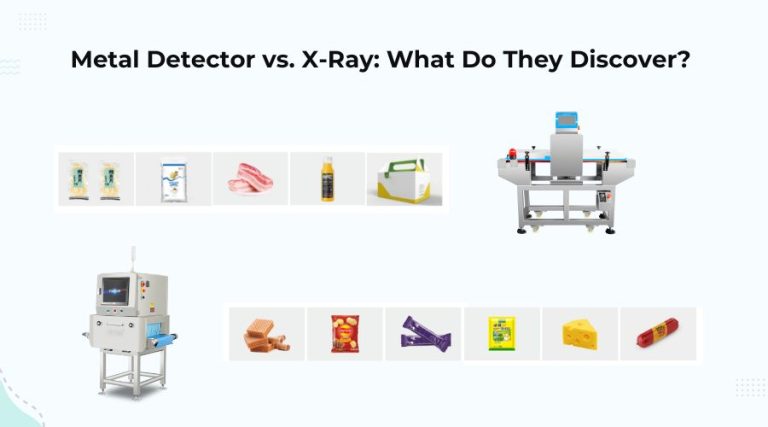

Metal Detector vs. X-Ray: What Do They Discover?

This is where it gets interesting. Let’s see what do metal detectors detect:

Ferrous metals (like iron and steel): Trivial to detect.

Non-ferrous metals (like aluminum and copper): Harder, but not impossible to detect.

Stainless steel: The hardest. Especially if the steel has low magnetic properties.

Now consider that in perspective with an X-ray inspection system. X-ray machine will find metal (ferrous and non-ferrous), glass, bones, stones, rubber, dense plastics, etc., in addition to the below. It will also find meat fat to lean ratio, product label visual inspection, defects and other uses.

All things considered, X-ray inspection is the winner when it comes to versatility. But don’t believe metal detectors can’t be helpful. They’re still required by many food manufacturers. X-ray inspection machine with greater capability, yet food metal detectors are equally as accurate and economical in identifying foreign metal items. In deciding between these two machines, the right one to choose is the one that is best suited to your production line, depending on your surroundings and the types of foreign material that are more likely to be incorporated into your production process.

Do Metal Detectors Detect Aluminum Packaged Products?

Here’s a common question: Do metal detectors detect aluminum? The answer: Yes — but not always well.

Aluminum is a non-ferrous metal. It’s less conductive and less magnetic. So many food metal detectors struggle to spot it, especially in small pieces. And if your product is packaged in aluminum foil, that adds another problem. Standard metal detectors often fail entirely in that situation.

But there’s a solution. Our Metal Detector for Aluminum Foil Packaged Products is specially designed for this challenge. It uses a conveyor metal detector with a special frequency that allows it to detect metal through aluminum packaging.

X-Ray Food Inspection: A Game-Changer

When you need a step up in detection power, X-ray food inspection is your go-to. It doesn’t just find metal. It can locate glass shards in sauces. It can detect bones in chicken fillets. Or plastic pieces in baked goods.

How? Because it doesn’t care about magnetism or conductivity. It looks at density differences. If something’s denser than the surrounding food, the X-ray inspection machine sees it.

Need a concrete example? Suppose you run a poultry plant. You’re processing thousands of chicken fillets daily. Tiny bone fragments are your enemy. A metal detector won’t help here. But a food X-ray machine will catch those fragments every time.

Which One Should You Choose?

That depends on your business. Ask yourself the following:

What kind of contaminants are likely in your products?

Are your products packaged ialuminum?

Is cost a big concern?

Do you need to detect non-metal contaminants?

Are you subject to strict food safety audits?

If you mostly need to detect metal — and your packaging doesn’t involve foil — a metal detector might be enough. Especially if budget is tight. You can even find rental metal detectors to keep costs down.

But if you’re dealing with high-risk products, high volumes, or aluminum packaging, go with X-ray food inspection. It’s more expensive, yes. But the detection coverage is superior.

Conveyor Metal Detectors vs. X-Ray Machines

Both technologies can be installed on conveyor lines. A conveyor metal detector scans products as they pass through a tunnel. Simple. Fast. Affordable.

A food X-ray machine also works on conveyor belts. But it needs more power. And more shielding. That’s why X-ray inspection machines are often found in higher-budget facilities — or where product liability risks are massive.

Food Industry Regulations

Both metal detectors and X-ray inspection for food industry are used to meet regulatory standards. Agencies like the FDA, BRCGS, and HACCP recommend or even require such systems. If you’re exporting to the EU or the US, expect to have a strong x-ray inspection system or metal detection policy in place.

Auditors love paperwork. So choose a machine with digital traceability and cloud reporting. It makes compliance audits much easier.

Let’s talk numbers. Metal detectors are more affordable upfront. They’re easier to maintain. And they usually don’t need special shielding. That makes them perfect for startups or low-risk environments.

X-ray inspection machines cost more. But they also detect more. Think of it as an investment. You’re paying to avoid product recalls, lawsuits, or damaged brand reputation.

Why Choose Easyweigh?

At Easyweigh, we’ve helped hundreds of food businesses choose between metal detectors and X-ray food inspection systems. Whether you need a compact conveyor metal detector, a high-speed food X-ray machine, or even advice on rental metal detectors, we’re here for you.

Our equipment is designed with precision and compliance in mind. We know that food safety isn’t just about avoiding fines — it’s about protecting your brand and your customers.

Real-Life Use Cases

Snack Manufacturer: Switched from metal detectors to X-ray inspection due to frequent glass complaints. Defect rate dropped 97%.

Dairy Plant: Uses both. Metal detectors for bulk milk powder. X-ray inspection machines for final retail packaging.

Meat Processor: Replaced old metal detectors with our food X-ray machine. Now detects bone fragments, missing before.

Conclusion

No matter your product, inspection is key. Some businesses thrive with metal detectors. Others need the advanced protection of X-ray inspection for food industry. Still not sure? That’s why we’re here. Reach out. Let us help you find the best fit for your production line.

Choose wisely. Your product’s quality — and your reputation — depend on it.

fAQs

What is the main difference between an X-ray inspection system and a metal detector?

The main difference is the type of contaminants they can detect. A metal detector can only detect metal contaminants like ferrous, non-ferrous, and stainless steel. An X-ray inspection system can detect a wide range of foreign material like glass, rubber, stones, plastic, and even bone fragments, depending on the density contrast.

Which is more appropriate to use for detecting aluminum packaged products—metal detectors or food X-ray machines?

Not all metal detectors can detect aluminum packaged products, especially if the food product is covered in aluminum foil. An X-ray inspection machine would be more suited in these cases since it can penetrate aluminum and determine whether there are contaminants inside.

Are X-ray machines safe to use in food processing?

Yes. Food X-ray machines comply with international food safety standards. They emit a very low dose of radiation—comparable to what you’d get during a short flight. The X-ray inspection for food industry is widely adopted and considered safe for both operators and food products.