Introduction

Metal detectors are ubiquitous, found in locations ranging from airport security lines to treasure hunts. However, their importance in industrial environments, particularly for ensuring food safety, is even greater. In industries such as food production, pharmaceuticals, and packaging, metal detection machines are vital for identifying and eliminating potential contaminants before products reach consumers. With increasing regulations and a heightened focus on safety, it is essential for manufacturers to understand how metal detectors work and what types of contaminants they can detect to maintain quality and compliance.

In this guide, we will cover everything you need to know: how metal detectors work, what do metal detectors detect, whether they can locate aluminum, and how technologies like conveyor metal detectors and bulk metal detectors safeguard production lines. We will also explore how these systems fit into HACCP protocols and automated production processes to ensure products are free from contamination and to prevent costly recalls in the food industry.

Let’s dive in.

How Does a Metal Detector Work? Understanding the Basics

A metal detector is an electronic device designed to identify the presence of metal nearby. It operates by transmitting an electromagnetic field and analyzing the signal that returns from any conductive material. Beyond security screenings, metal detectors are particularly vital in food and pharmaceutical production, as they ensure product safety.

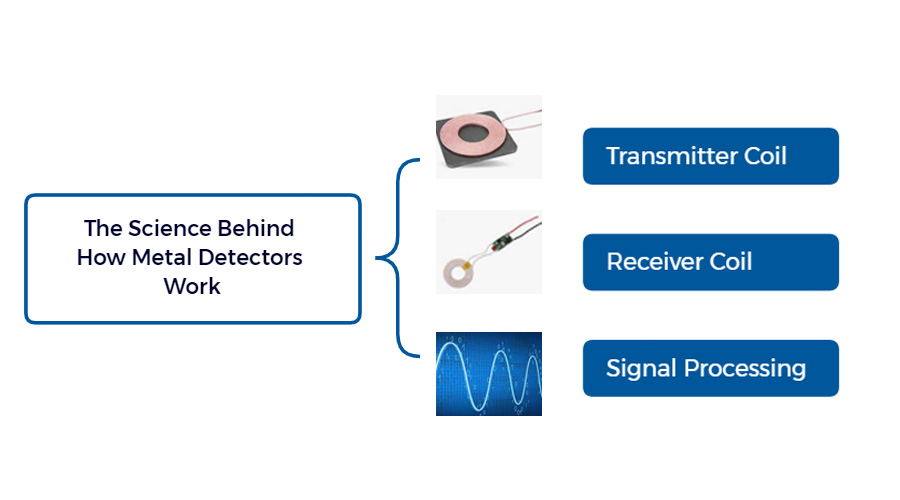

The Science Behind How Metal Detectors Work

So, how does a metal detector work? It is based on the principle of electromagnetic induction. Here’s a simple breakdown of the process:

Transmitter Coil: This part generates an electromagnetic field when powered on.

Receiver Coil: This coil detects any disruptions in the electromagnetic field.

Signal Processing: When a metal object passes through the field, it distorts the electromagnetic field. The receiver coil picks up this change, and the metal detector interprets it as a detection event.

Once a metal object is detected, the device triggers alert. In food processing, the metal detection system may even automatically reject the contaminated item from the conveyor line.

What Do Metal Detectors Detect? Can Metal Detectors Find Aluminum?

What Do Metal Detectors Detect?

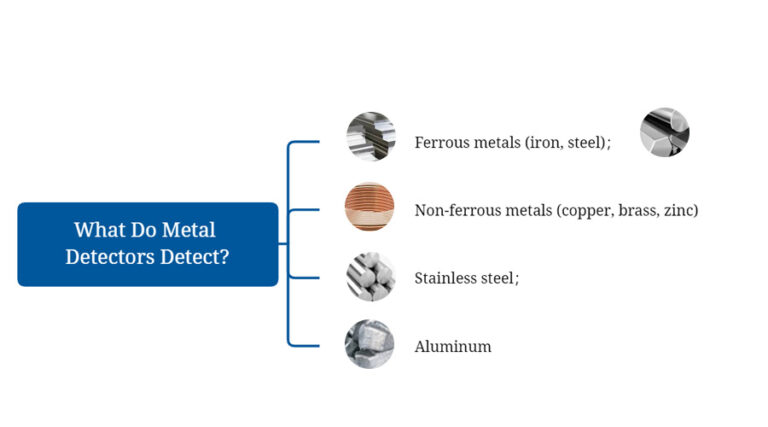

Metal detectors detect a wide range of metals, including:

- Ferrous metals (iron, steel)

- Non-ferrous metals (copper, brass, zinc)

- Stainless steel

- Aluminum

They can detect items such as bolts, screws, wire fragments, foil, and even tools that might accidentally contaminate food or packaging lines.

Can Metal Detectors Find Aluminum? Does Aluminum Set Off Metal Detectors?

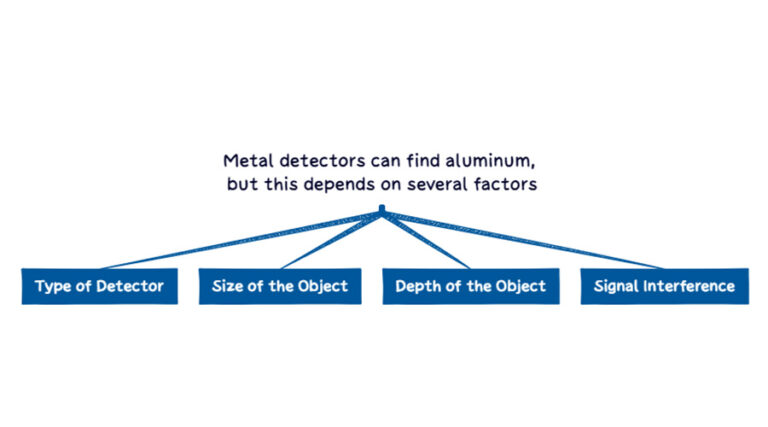

Yes, metal detectors can indeed find aluminum, but this ability depends on several factors:

Type of Detector: The technology used (pulse induction vs. very low frequency) affects detection capabilities.

Size of the Object: Larger aluminum items are generally easier to detect than smaller ones.

Depth of the Object: The deeper an object is buried, the more challenging it can be to detect.

Signal Interference: Factors such as product signal interference, especially in food applications, can impact detection.

Although aluminum is non-magnetic, it is still conductive and can trigger metal detectors machines, particularly the advanced models used in the food industry. However, detecting metal objects in aluminum foil packaging can be more challenging without proper phase adjustment or the use of multifrequency metal detectors.

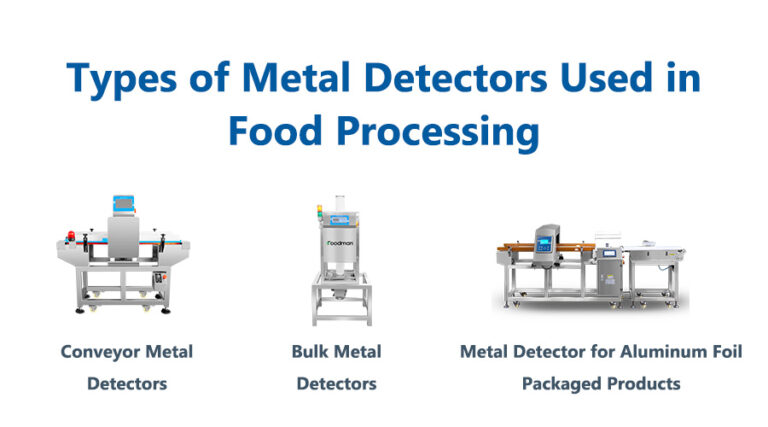

Types of Metal Detectors Used in Food Processing

How They Work: These dynamic metal detectors are integrated into conveyor systems to automatically scan products moving on production lines. They often use a combination of VLF or multi-frequency technology.

Best For: Food metal detectors for food ensure products are free from metal contamination during processing. They provide high-speed detection without disrupting production flow, making them ideal for large-scale industrial environments such as food production and packaging lines.

How They Work: Bulk metal detectors are specialized for detecting larger metal pieces in bulk materials, such as grains, powders, or liquids. They use magnetic fields and radio waves to scan the bulk material for contamination.

Best for: Ideal for industries processing bulk materials like grains, dairy, and pharmaceuticals. It’s particularly effective in high-volume processing systems aimed at preventing metal contamination in bulk products.

How They Work: Metal detectors are essential for detecting foreign metal contaminants in aluminum foil-packaged products, including ferrous, non-ferrous metals, and stainless steel, even within the foil layers.

Best For: Aluminum foil packaging is often used in food because of its excellent barrier properties, effectively preventing moisture, light and contamination. However, this packaging material also presents unique challenges in metal detection. Aluminum foil metal detectors can detect metal contaminants in products packaged in aluminum foil.

Metal Detector Systems in Food Safety and HACCP

In the context of HACCP (Hazard Analysis Critical Control Point), metal detectors are essential for identifying and removing physical hazards in food production.

How Metal Detectors Fit into HACCP

Critical Control Point (CCP): A metal detector is often designated as a CCP where potential physical contaminants are identified and managed.

Food Safety Compliance: Regulations often require manufacturers to use metal detector systems to prevent contamination-related recalls.

Integration with Automated Systems: Modern conveyor metal detectors can be integrated with automated production systems for real-time monitoring and rejection.

Best Practices for Food Metal Detectors

To ensure optimal performance of metal detectors in food manufacturing, follow these guidelines:

- Regularly use test cards to verify detection sensitivity.

- Calibrate the machine according to the specific product type (wet, dry, salty, or acidic).

- Monitor performance and maintain audit-ready documentation.

- Integrate with rejection systems to effectively remove contaminated products.

By implementing a robust metal detection solution, manufacturers not only comply with food safety standards but also protect their brand reputation and consumer health.

How to Choose the Right Metal Detector for Your Operation

Selecting the appropriate metal detector machine involves understanding your product, the type of packaging and the operational environment.

Key Factors to Consider

Product Properties: Moist or conductive foods can sometimes mimic metal, leading to false positives. Select a food metal detector specifically designed to overcome these challenges.

Packaging Materials: Foil or metallized film packaging may interfere with detection. In such cases, consider x-ray inspection as an alternative.

Throughput Speed: Ensure that the metal detection system can inspect products at the speed of your production line.

Reject System Compatibility: Your detector should seamlessly integrate with pushers, air blasts, or diverters for the automatic removal of contaminants.

Environmental Conditions: Is your facility suitable for washdown? Opt for waterproof, stainless-steel detectors for wet environments.

Advanced Metal Detection Technologies

Many newer metal detectors come equipped with features such as:

- Automatic calibration

- High-resolution touchscreens

- Connectivity for data logging and audit trails

- Compatibility with HACCP monitoring software

Whether you are working with packaged snacks, bulk grains, or fresh produce, choosing the right metal detection system is essential for ensuring optimal performance and maintaining consistent food safety.

Conclusion

Understanding how metal detectors operate is essential for industries where safety and quality control are crucial. These devices, which range from basic electromagnetic models to advanced systems used in high-speed automated production, play a vital role in detecting and eliminating physical contaminants.

Whether you require a bulk metal detector, a conveyor metal detector, or a metal detector specifically designed for food processing, selecting the appropriate system and integrating it into your HACCP plan will help protect your products, prevent costly recalls, and maintain your reputation in the marketplace.

FAQs

A conveyor metal detector is utilized in production lines to automatically inspect products as they pass through. If metal contamination is detected, the system removes the affected item from the line.

Food metal detectors are specifically designed for the food industry and comply with HACCP (Hazard Analysis and Critical Control Points) food safety standards. They are more sensitive and adapted to factors like moisture and salt content.

Yes, in several industries, metal detectors are essential for HACCP plans and regulatory compliance to ensure the safety and integrity of food products.