Introduction

Metal detectors are absolutely imperative in ensuring food safety in food processing industry. Metal fragments are impurities that could destroy the quality of foodstuffs and develop severe health issues. The most important tool to prevent this issue is the metal detector. What types of metal detectors need to be utilized in different types of food processing? How do they ensure food safety? In this tutorial, we will examine some of the different types of metal detectors used in the industry, how they work, and why they are so important in maintaining food safety standards.

What Is a Metal Detector

A metal detector is a device that uses electromagnetic fields to detect the presence of metal objects. Metal detecting systems in the food industry are designed to identify ferrous, non-ferrous, and even stainless steel contaminants in food products. These systems are critical in ensuring that food products are free from harmful metal contaminants before they reach consumers. Ensure that products containing metal contaminants are promptly removed from food production lines.

When food passes through a metal detector, the system generates an electromagnetic field. If the food contains any type of metal, the field is disturbed. The metal detector then detects this disturbance and signals an alert, indicating the presence of metal contaminants in food. At the same time, the rejection system on the metal detector will promptly remove defective products from the production line.

Types of Metal Detectors Used in the Food Industry

There are several types of metal detectors that are commonly used in food processing to ensure food safety. Each type is designed for specific applications depending on the nature of the food and the type of contamination.

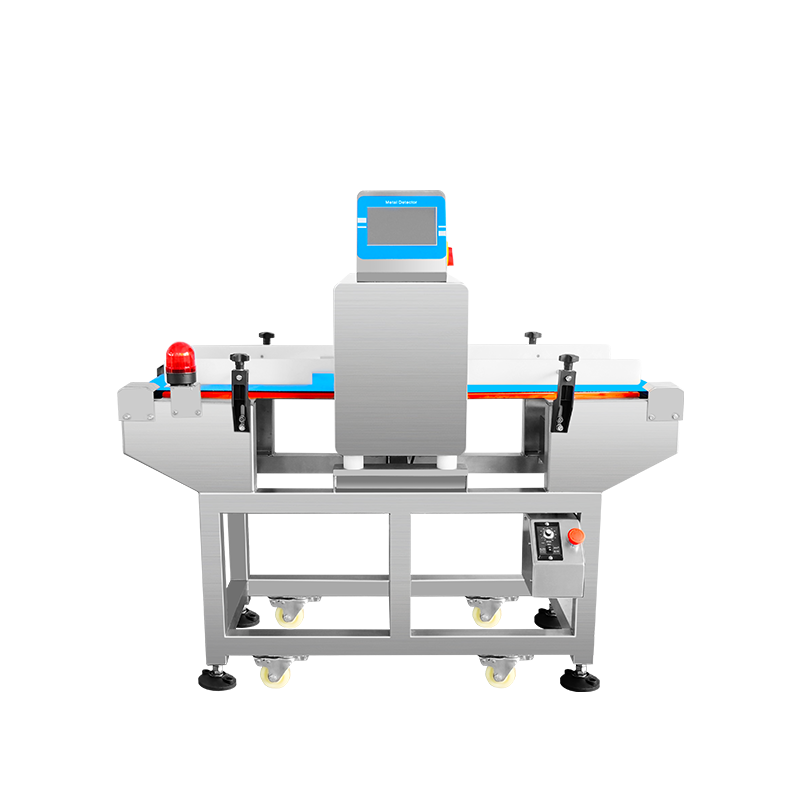

Conveyor Metal Detector

A Conveyor Metal Detector is one of the most common inspection systems in the food industry. Installed directly on production lines, it checks both packaged and unpackaged products as they move along a conveyor belt. With high sensitivity, it can detect ferrous, non-ferrous, and stainless-steel contaminants, helping manufacturers maintain strict food safety standards while keeping production fast and efficient.

Metal Detector for Aluminum Foil Packaged Products

The Metal Detector for Aluminum Foil Packaged Products is specially designed to inspect foods wrapped in aluminum foil, where standard detectors may struggle. This food metal detector effectively shields aluminum foil packaging without affecting the detection of internal metallic foreign objects, enabling precise identification of ferrous impurities such as iron and steel. It ensures safe and reliable inspection for items like chocolate bars, dairy products, and ready-to-eat meals packaged with foil.

Free-Fall Metal Detector

A Free-Fall Metal Detector is commonly used in the food industry for inspecting products like grains, powders, spices, and other bulk materials that move through gravity-fed pipelines. As the product drops through the detector, it quickly identifies and removes any metal contaminants before the bulk products continue further in processing. Low carryover rate of powdered product during the removal process. This method is fast, efficient, and perfect for high-volume production lines where speed and accuracy matter.

What Is Physical Contamination in Food?

Physical contamination means any foreign object that shouldn’t be in food, such as metal, glass, or plastic. These contaminants can harm people if they are eaten. Metal detectors are specifically designed to find physical contamination, especially metal fragments, to keep the food safe. However, when it comes to detecting foreign objects such as bones or glass, an X-ray machine is required for inspection.

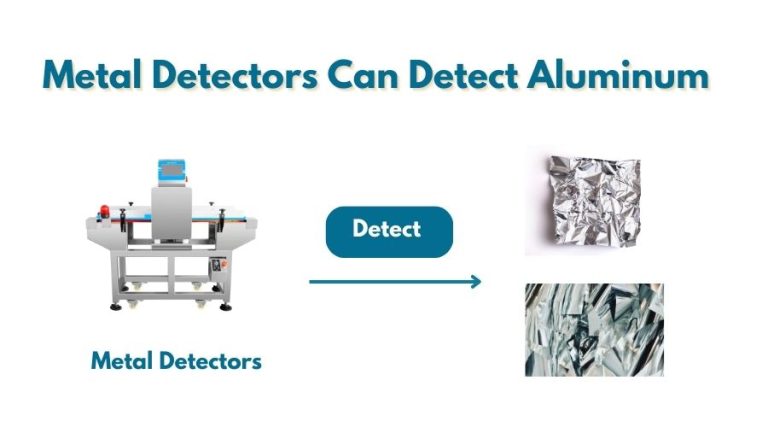

Do Metal Detectors Detect Aluminum?

A common question in the food processing industry is: “Do metal detectors detect aluminum?”

Yes, metal detectors can detect aluminum. They are designed to find non-ferrous metals. Non-ferrous metal detectors are able to identify metals like aluminum, copper, and others that don’t have magnetic properties. It can set off alarms in non-ferrous metal detectors.

Metal detectors play a key role in helping food companies follow food safety regulations. Regulatory bodies like the FDA and EU have strict rules that food producers must follow to prevent contamination. Metal detectors help food manufacturers meet these rules and provide safe food to consumers. Some key benefits include:

HACCP (Hazard Analysis Critical Control Point) guidelines, which require regular checks for metal contamination.

Food safety regulations that require inspections for foreign objects like metal.

Ongoing product inspections to ensure food meets food safety standards.

By using metal detectors, food manufacturers can stay compliant with these regulations and protect both their customers and their brand reputation.

Choosing the best metal detector for your food production line depends on several factors:

Type of Metal: Think about the types of metals you need to detect, whether it’s ferrous, non-ferrous, or stainless steel.

Food Type: Consider the food you are processing. Is it solid, liquid, or packaged? This will help determine which detector works best.

Production Speed: Some detectors are better for high-speed production lines, while others are better for slower operations.

Metal Size: Make sure the detector is sensitive enough to detect small metal fragments.

Conclusion

In the food processing industry, metal detectors are crucial for maintaining food safety standards. These systems help prevent contamination from metal fragments and ensure that food products are safe for consumers. Whether you are using a ferrous, non-ferrous, or stainless steel metal detector, choosing the right one is key to keeping your production line safe and compliant with food safety regulations. Regular use of metal detectors not only protects your customers but also protects your business from costly recalls and potential health risks.

FAQs

What are tablet or capsule metal detectors used for?

Pharmaceutical, nutraceutical, and confectionery use them to a large extent, where detection of small pieces in small things like tablets, candies, or capsules is of utmost concern.

What is the operation with liquid or paste product?

Pipeline metal detectors are used for liquids, sauces, and slurries. They are installed on pumps or pressure systems and will not interrupt product flow in sensing small contaminants.

Will metal detectors detect products wrapped in aluminum foil?

Yes. Standard detectors are unable to pass through foil, but ferrous-in-foil metal detectors have been invented to detect ferrous contaminants in products wrapped in aluminum like chocolates, dairy, and ready-to-eat meals.